PREPARATION OF MACROPOROUS STRUCTURES WITH UNIDIRECTIONAL FREEZING

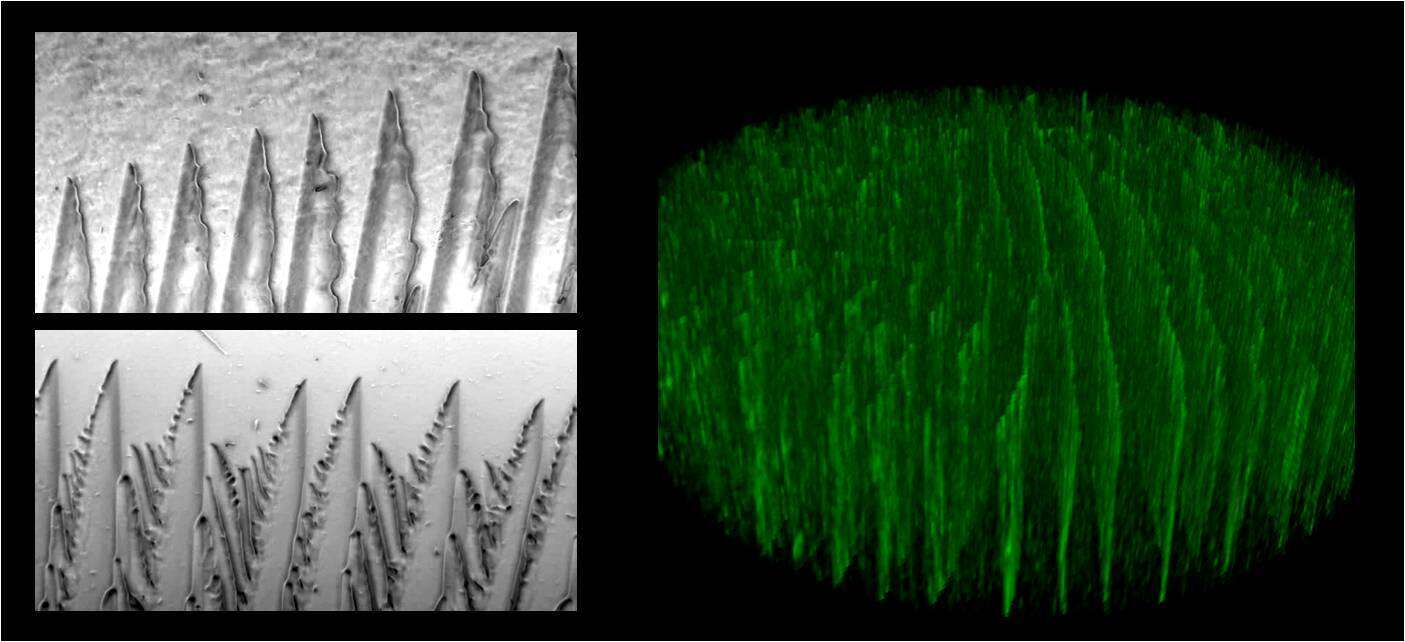

Control of the microstructure is one of the keys to achieve the desired performance of material. Ice templating method allows fabrication of various microstructures scaled from few to few hundred microns. Ice templating, which is also known as freeze-casting, takes advantage over controlled ice growth to impose microstructure into second material that dispersed/dissolved in water. During the freezing, ice rejects and traps the suspended particles in between the ice crystals. In such way suspended particles become inverted replica of the ice crystals. Cooling rate and temperature gradient allows control of the ice crystals shape, and consequently enable control of the material microstructure. In our study we focus on influence of cooling regimes and ice shaping additives on microstructure and mechanical properties of different aqueous suspensions, such as nano-crystalline cellulose suspensions, emulsions and others. We show that control of the freezing process allows controlling the microstructure of the scaffold and makes this approach very attractive for various applications such as material and food engineering.

This work was supported by the FP7 EU research and innovation funding program.

Powered by Eventact EMS