ELECTROCHEMICALLY-ENHANCED SURFACE PLASTICITY OF STEELS

2State Key Laboratory for Advanced Metals and Materials, University of Sciences and Technology Bejing, Beijing

There are serious problems in formability of alloys which are relatively hard and brittle under ambient temperatures, e.g., in cold extrusion and drawing processes. It is known that electrochemical surface treatment can decrease the residual stresses and the hardness of the surface layer as a result of the chemomechanical effect, and also to improve the plastic formability, e.g., by deep drawing of high strength alloys.

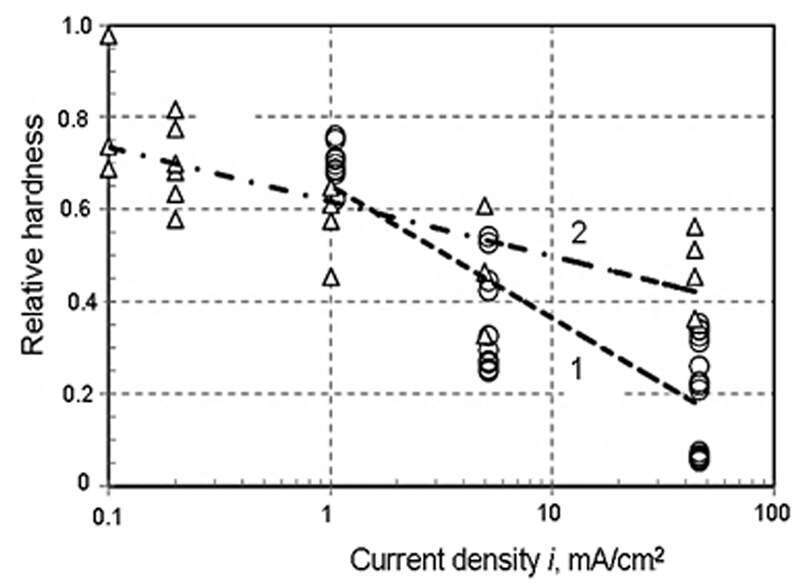

The present research is aimed at improvement of the surface ductility of carbon steels SAE 1020 and 1070 as well as FeSi6.5 steel under anodic polarization by study of its dependence on current density (i), composition and acidity of sulfuric and hydrochloric acids; sodium and potassium chlorides. The hardness in solution was measured at points located between two adjacent indentations previously made in air. The relative Vickers hardness RVH = VHsol/VHair was determined as the squared ratio of the indenter penetration depth in air and in solution (hair/hsol)2.

Under the anodic polarization of steels, the relative hardness decreased with increasing of current density with a good linear correlation between log (i) and hardness, accordingly to the theory of the chemomechanical effect.

Figure: Effect of current density on hardness of FeSi6.5 alloy in 0.5M H2SO4 (1) and 0.3M HCl + 0.6M NaCl (2) solutions as compared to that in air at the load of 2.9 N.

Powered by Eventact EMS