3D PRINTING OF GRADED TiC/STEEL COMPOSITES

2Mechanical Engineering, Columbia University, New York City, New York

3Manufacturing Demonstration Facility, Oak Ridge National Laboratories, Knoxville, Tennessee

4Mechanical, Aerospace and Biomedical Engineering, University of Tennessee, Knoxville, Tennessee

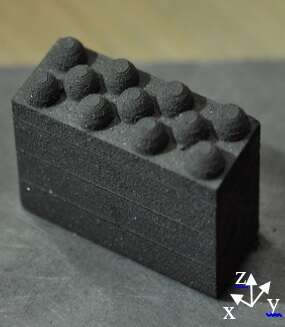

TiC-carbon steel composites display high hardness and toughness, which depend on a metal to ceramic ratio. The mechanical properties of the composites may be also changed by using titanium carbide with various stoichiometry. According to our previous results and thermodynamic analysis [1] the stoichiometry of the carbide phase (x in TiCx, x varies from 0.5 to 0.98) dictates the carbon content in a steel after high temperature interaction and its possibility undergo thermal treatment. Based on this phenomenon the graded TiC-steel composites were fabricated by free infiltration of porous TiC preforms with liquid steel [2]. For the fabrication of complex shape graded composites we used Binder Jet 3D printing technology. Design of the microstructure of both the metallic and the ceramic phases in the composite was based on an appropriate choice of the carbon content in the carbide phase and in the steel. 3D printed specimens (Fig. 1) with about 50% porosity were infiltrated by 1060 steel at 1550°C for 30min. The infiltrated specimens were quenched in oil from 850°C. The gradient of the martensite fraction in Z-direction in the composites provides gradient of hardness from 500 to 1300MPa.

Fig. 1: Graded TiCx green bodies (x varies in Z direction) fabricated by Binder Jet 3D printing.

References:

- Frage N., "Interaction between Nonstoichiometric Titanium Carbide and Fe-C Alloys", Metallurgical and materials transactions B, Volume 30B (1999), Pg. 857-863.

- Sabatello S., Frage N., Dariel M.P., "Graded TiC-based cermets", Materials Science & Engineering A288 (2000), Pg. 12-18.

Powered by Eventact EMS