Fe-RICH FeCrAl ALLOYS MICROALLOYED WITH Zr USED IN NUCLEAR POWER PLANT OF 4R GENERATION

2Materials Technology and Welding Department, Engineering and Management of Technological Systems Faculty, University Politehnica of Bucharest, Bucharest

3Institut für Hochleistungsimpuls - und Mikrowellentechnik (IHM), Karlsruhe Institute of Technology, Karlsruhe

FeCrAl-based alloys are under consideration for their potential to be used as structural materials in advanced nuclear reactors cooled with oxygen containing molten Pb or Pb-Bi alloys. By forming a slowly growing aluminum-rich scale, these alloys are resistant to high temperature corrosion, fretting and erosion-corrosion. These alloys show also a good irradiation resistance. The protective oxide layer must be regenerable, with good mechanical resistance and with high adhesive strength. To improve the mechanical and chemical properties of the oxide layer, FeCrAl-based alloys are microalloyed with reactive elements like Zr, Ti, Y, Hf, Ce, in the 1-3 wt. % range. These elements presenting a very high affinity to the oxygen are capable to stabilize the alumina structure and to improve the scale adherence to the metallic substrate. FeCrAl-based alloys microalloyed with Zr were prepared by arc melting, starting from a mixture of commercial pure metals, using VAR (Vacuum Arc Remelting) unit, under high purity argon atmosphere. The four experimental FeCrAl-based alloys contain the following quantities of zirconium: 0.5 wt. %; 1.0 wt. %; 1.5 wt. % and respectively 2 wt. %. The microhardness values for the experimental alloys were in the range 156 - 166 HV0.2. EDAX analyses have been performed to determine chemical composition of the oxide layer and of the bulk of sample, while SEM analysis has been done to determine the microstructural properties. The results have shown that during high-temperature oxidation experiments performed in air, the FeCrAl-based alloys have formed oxide layers with different texture, that are rich in elements such as Al and Zr.

|

FeCrAl samples obtained in VAR unit. |

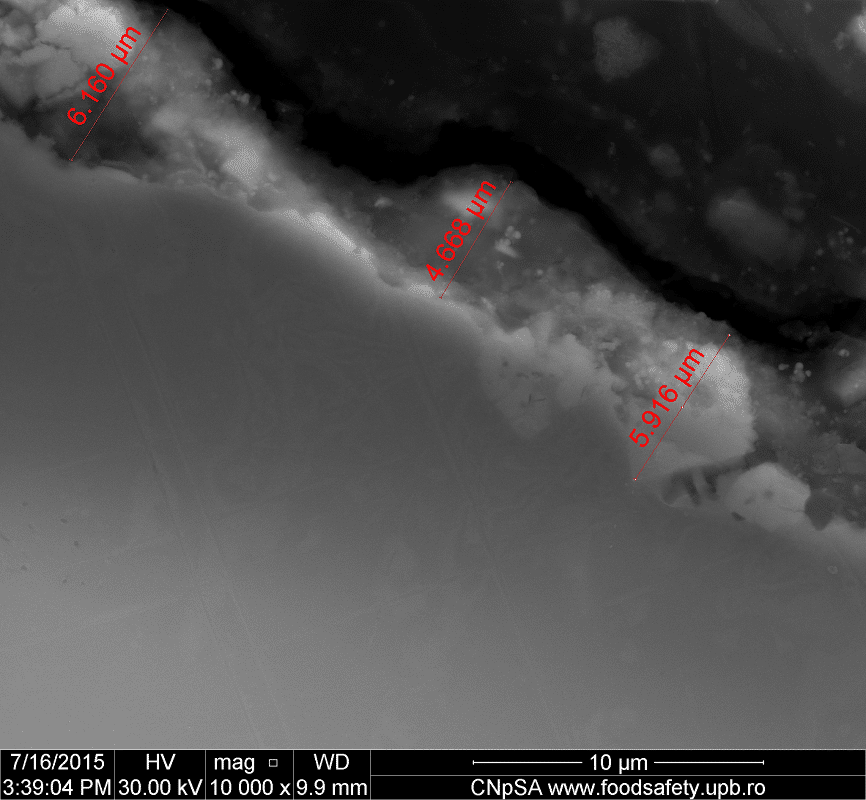

Oxides layers on the marginal crust of FeCrAl. |

Powered by Eventact EMS