STUDY OF DILUTION EFFECTS IN THE JOINT BRAZED WITH Cu-Ag ALLOY FOR STAINLESS STEEL COMPONENTS

2Engineering and Management of Metallic Materials Obtaining Department, , Materials Science and Engineering Faculty, University Politehnica of Bucharest, Bucharest

3Quality Management, SUDOTIM AS Timisoara, Timisoara

4Materials Science, Ben-Gurion University of the Negev, Beer-Sheva

5Microstructural Analysis, METAV-CD, Bucharest

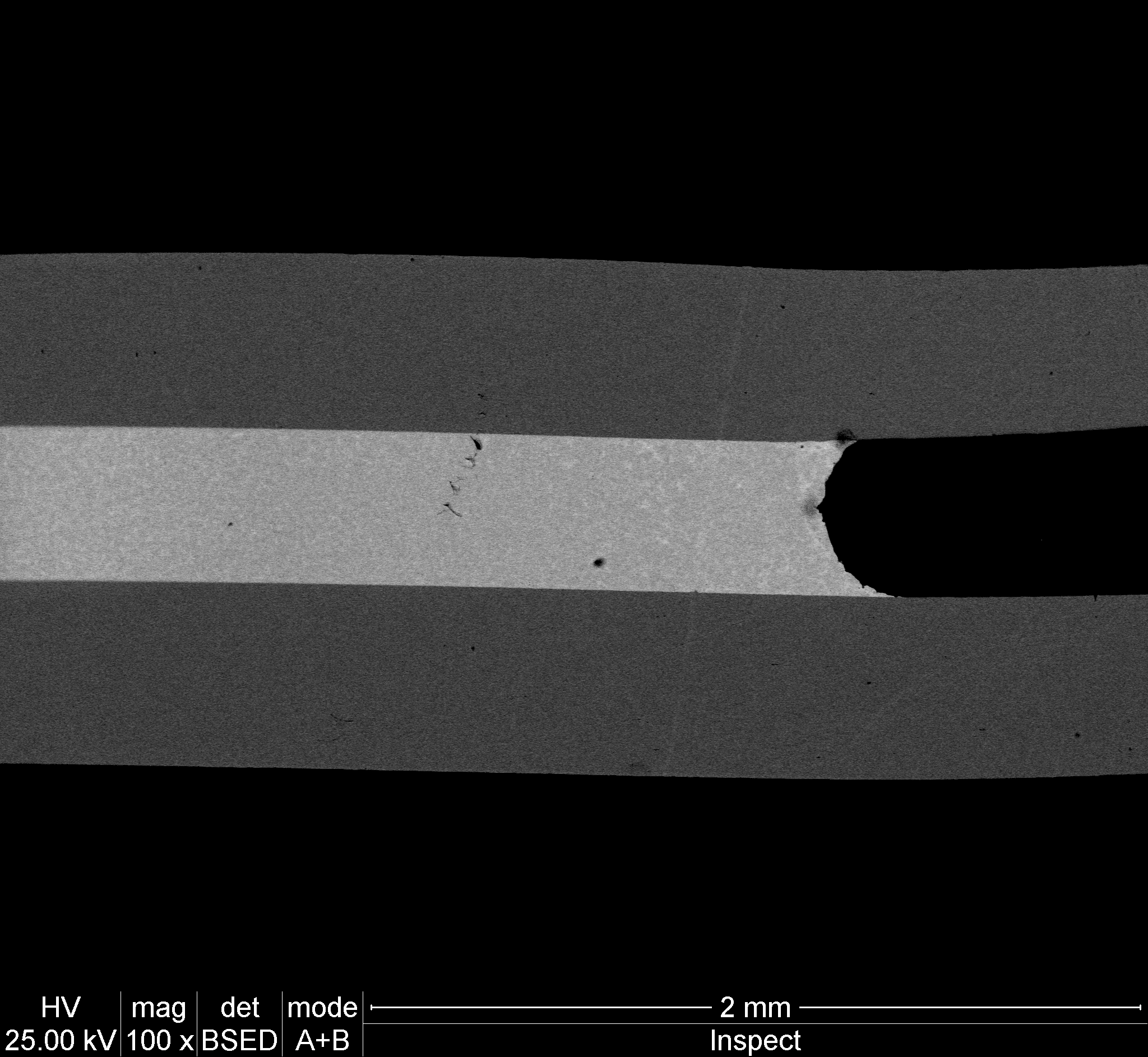

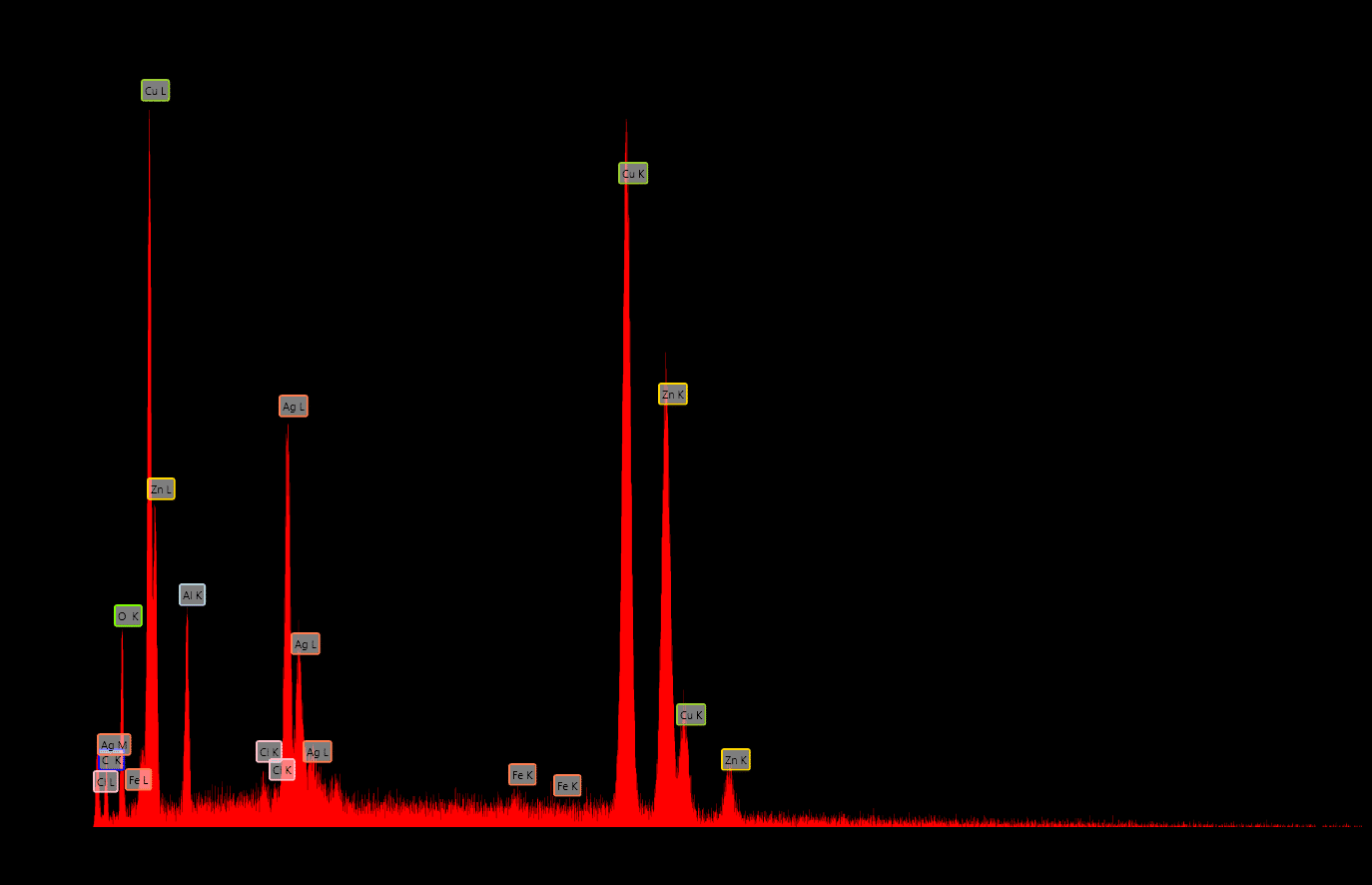

The brazed joints made in stainless steel can be frequently exposed to water or vapor during service. This specific medium can promote interfacial corrosion of failure of the joints. The special silver-copper brazing filler metal allows to avoiding the problems of interfacial corrosion and improves the strength of the joint. Most stainless steel types, with the exception of titanium or niobium stabilized grades, can be brazed. For brazing stainless steels in air with flux low-temperature silver brazing alloys are generally used. In the research paper two different type of brazing filler material has been used for brazing stainless steel component and then the dilution phenomenon has been studied, in terms of chemical element displacement from the brazed separation interface. To be able to enter in the narrow gap of the brazed joint, the brazing rod contains a double special covering that allows obtaining a difference between the melting temperature of coating and of the metallic rod. In this way, the filler metal can spread rapidly and fill completely the gap. Composite coatings contain 60 to 65% deoxidation flows, in accordance with EN 14045: 1999, 15 to 20% plasticizers and 10 to15% binder. They also contain nano-powders with suitable properties, such as wetting and deoxidation agents, to improve the diffusion and to increase the strength tear. Analyze of diffusion line was performed using electron microscopy SEM and EDX spectrometry. Microhardness measurement has enabled assessing the hardening effect of filler metal and diffusion areas.

|

Overlapp joint |

Corner joint |

|

Elemental analysis |

|

Powered by Eventact EMS