DEVELOPMENT OF ADVANCED Bi-Te BASED TEG FOR HIGHER EFFICIENCY PV-TE HYBRID SYSTEM: NUMERICAL MODELING AND EXPERIMENTAL VERIFICATION

2Department of Physics, Nuclear Research Center Negev, Beer-Sheva

In an ever changing world the request for new alternative energy resources enables new technological developments and brings society one step closer to a cleaner environment. Developing of a hybrid photovoltaic- thermoelectric (PV-TE) system can be a novel solution: Sunlight at high concentration illuminates the PV, thereby producing electrical power while at the same time heating it up due to the fact that most solar cells do not utilize the IR spectrum. This heat is transferred to a thermoelectric module attached to the PVs` bottom end which produces additional electric power.

In order to improve the efficiency of this hybrid system, an advanced thermoelectric power generation devices for temperatures of up to 250oC is needed. In the current research, for approaching practical thermoelectric power generation devices, capable of operation at such temperatures, Bi0.82Sb0.18 alloy was considered as a lead-free high temperature (<250oC) solder composition for bonding of n-type Bi2Te2.4Se0.6 and p- type Bi0.4Sb1.6Te3 legs into Cu bridges. Fine contacts with low electrical contact resistances in the range of ~1.5±0.5 mWmm2, were observed upon soldering at 350oC.

A steady state finite element simulation of a PV-TE system was made using the COMSOL multi-physics platform, shows that with the properties of the materials that developed at our laboratory, n-type Bi2Te2.4Se0.6 and p- type Bi0.4Sb1.6Te3, there is an improvement of the efficiency of up to 3 times higher than using a commercial BixTe1-x device.

![]()

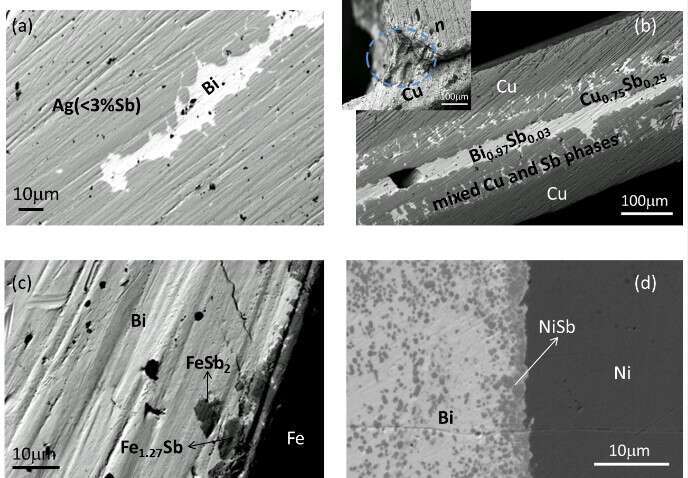

SEM micrographs following Bi0.82Sb0.18 soldering of similar Ag (a), Cu (b), Fe (c) and Ni (d) plates to each other at 450C. The inset in (b) shows a strong interaction zone and partial melting of the leg in the vicinity of contact between the n-Bi2Te2.4Se0.6 leg and the Cu metallic bridge following soldering at 450C.

Powered by Eventact EMS