Influence of wafer rotation rate on hillocks formation in (100) HgCdTe layers grown by MOCVD on GaAs epi-redy substrates

2Vigo System S.A., -

The mercury cadmium telluride (HgCdTe) is still the main candidate for the middle wavelength infrared (MWIR) as well as the long wavelength (LWIR) infrared detectors. Its unique position is dependent on three key features: composition-dependent tailorable energy band gap, large optical coefficients that enable high quantum efficiency, and favorable inherent recombination mechanisms that lead to long carrier lifetime and high operating temperature. Additionally, the development of advanced epitaxial techniques such as molecular beam epitaxy (MBE) and metal organic chemical vapor deposition (MOCVD) allows the construction of complex HgCdTe heterostructure-based IR detectors.

One of the important parameters determining properties of devices is a number of structural defects. Structural defects on HgCdTe films depend on the growth techniques, growth conditions [1] and crystallographic orientation [2,3]. HgCdTe layers grown by MOCVD with (111)B orientations will twin [4]. The HgCdTe growth on the (100) orientation in turn shows the presence of surface pyramid-shaped macrodefects known as “hillocks”, with a height often greater than the thickness of the HgCdTe layer.

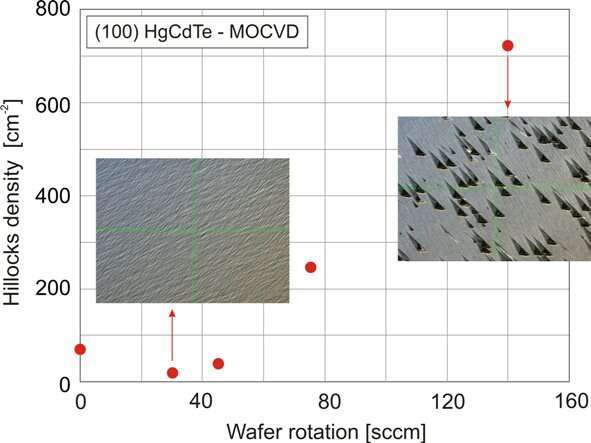

In this paper, we present the method of reduction of hillock macrodefects formation in (100) HgCdTe layers grown by MOCVD on GaAs epi-redy substrates. In our experiment, hillocks density was decreased to <102 cm-2 using a low wafer rotation rate. The high wafer rotation rate results even an order of magnitude higher hillocks density and more uniform arrangement.

Fig. 1. Density of hillock macrodefects on (100) HgCdTe layers as a function of wafer rotation rate.

- L.H. Zhang, and C.J. Summers, J. Electron. Mater. 27, 634 (1998).

- G. Cinader, A. Raizman, and A. Sher, J. Vac. Sci. Technol. B9, 1634 (1991).

- L.A. Almeida, M. Groenert, J. Markunas, and J.H. Dinan, J. Electron. Mater. 35, 1214 (2006).

- P. Capper, C.D. Maxey, P.A.C. Whiffin, B.C. Easton, J. Crystal Growth 96, 519 (1989).

Powered by Eventact EMS