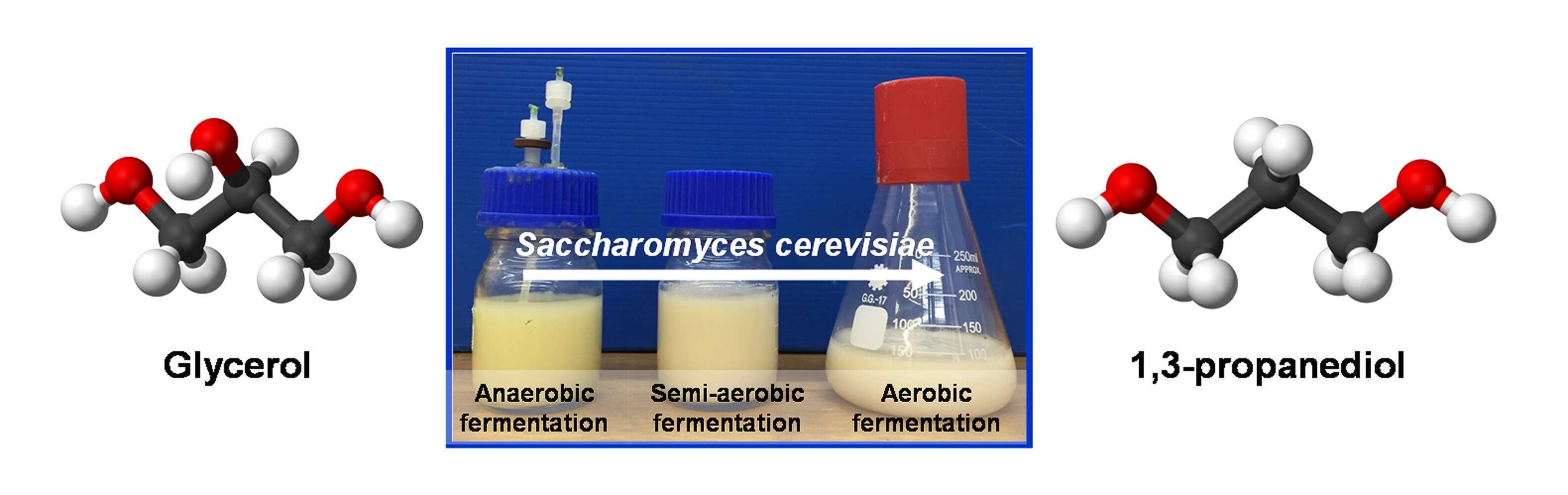

Conversion of Glycerol to 1,3-Propanediol via Fermentation by Saccharomyces Cerevisiae

2The Mina and Everard Goodman Faculty of Life Sciences and Institute for Nanotechnology and Advanced Materials (BINA), Bar-Ilan University, Ramat-Gan

The conversion of biorenewable feedstock for the production of valuable materials has become an important research trend due to the depletion of non-renewable resources and increasing global energy demand. Once considered a valuable by-product, crude glycerol is now becoming a ‘waste product’ due to the rapid growth of biodiesel industry. It is, therefore, crucial to develop environmental-friendly solutions for glycerol waste and facilitate the sustainability of the biofuel market. One of the most promising strategies for glycerol utilization is the production of commercially-valuable propanediols through selective hydrogenolysis, providing a green and economically-competitive route from a renewable carbon source rather than non-renewable petroleum. 1,3-propanediol (1,3-PDO) is a high-value specialty chemical, usually produced by the reduction of glycerol and used primarily in polyester fibers, films, and coatings. While the chemical and bacterial syntheses of 1,3-PDO are well-known, we report for the first time the possibility of converting glycerol to 1,3-PDO by a fungal strain. Synthesizing 1,3-PDO by biological means is extremely lucrative, and to the best of our knowledge, this is the first study to develop an optimized process for the production of the value-added chemical 1,3-PDO from the industrial waste glycerol via fermentation using the biocatalyst instant baker`s yeast (Saccharomyces cerevisiae). Various glycerol fermentation types (aerobic, semi-aerobic, and anaerobic) were tested at different reaction temperatures (25, 30, and 37 °C) to optimize the process. Under optimal conditions (anaerobic fermentation at 25 °C), 42.3 wt% 1,3-PDO yield was achieved with 93.6 wt% glycerol conversion, corresponding to ~60% of the theoretical 1,3-PDO yield.

Powered by Eventact EMS