Directed Assembly of Nano Particles by a Modulated Photo-Induced Microbubble

2Casali Center for Applied Chemistry, Institute of Chemistry, The Hebrew University of Jerusalem, Jerusalem

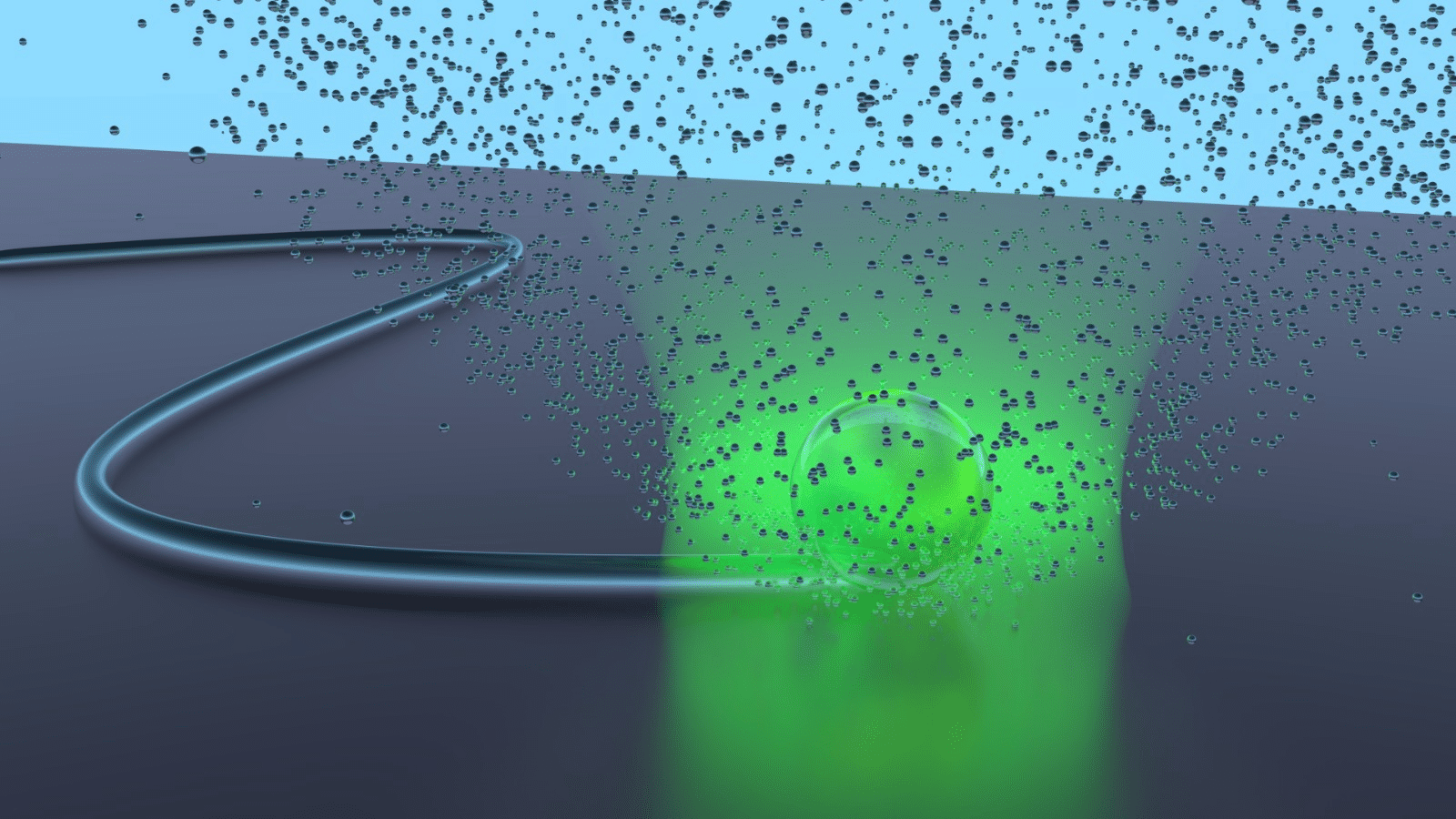

The laser induced microbubble technique (LIMBT) has been previously demonstrated for assembly of various materials. The principle of this method is that a microbubble formed by laser heating leads to material deposition at the bubble/substrate interface. Moving the focused beam relative to the sample results in the migration of the microbubble and constant deposition of additional material. The major limitation of this technique is its instability, resulting in non-continuous deposition.

Here we show how modulation of the laser, thus controlling the construction and destruction rate of the microbubble, allows formation of significantly thinner and more continuous patterns. We verify the continuity of the formed patterns by measuring the conductance of deposited metallic nanoparticles.

We furthermore apply this improved technique to construct more complex structures than previously possible using metals, oxides, polymers and various combinations of the former (hybrid structures). This exemplifies the ability of this method to be used for various foreseen applications such as transparent conductors and sensors.

Powered by Eventact EMS