Chloride as a Powerful Auxiliary Reagent in the Electroless Synthesis of Silver Nanostructures

2Department of Materials and Interfaces, Weizmann Institute of Science, Rehovot

To facilitate the implementation of nanomaterials, there is a strong need for innovation beyond cleanroom processing and for flexible, simple and robust synthetic routes to nanomaterial fabrication. Here we demonstrate the application of a facile wet-chemical method of electroless plating for achieving controlled preparation of silver nanostructures of varying morphology. The process can be applied to substrates of different compositions and shapes, can be performed without complex instrumentation, and is readily scalable.

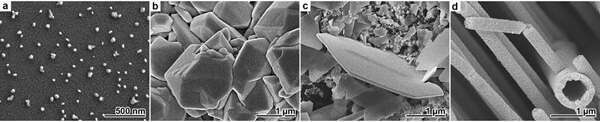

Specifically, we show that the strong interaction between silver and chloride ions can be utilized to adjust the product morphology, ranging from island-like nanoparticle deposits through closed and shape-controlled thin films to complex nanostructures derived thereof (Fig. 1). Chloride can be employed to modify the nucleation process on a seeded substrate. Depending on the nucleation distance and the size of the plated nanoparticles, island-like, percolated, or closed silver nanofilms can be created. We discuss the effect of chloride addition to an electroless plating bath on the deposition kinetics and the shape of the deposited particles.[1] Due to the high conformity of the reaction, it can also be applied to nanomaterial templates, allowing the synthesis of complex micro- and nano-architectures.[1,2]

Various applications of such nanoparticle films can be envisioned, depending on the silver morphology: Separated silver nanoparticle films can exhibit defined localized surface plasmon peaks and may be useful for dark-field microscopy, intensely roughened films can be used to construct self-cleaning coatings,[1] and self-supporting silver nano-networks can serve as efficient electrocatalysts.[2]

[1] F. Muench, B. Juretzka, S. Narayan, A. Radetinac, S. Flege, S. Schaefer, R.W. Stark, W. Ensinger. New J. Chem. 2015, 39, 6803–6812.

[2] F. Muench, E.-M. Felix, M. Rauber, S. Schaefer, M. Antoni, U. Kunz, H.-J. Kleebe, C. Trautmann, W. Ensinger. Electrochim. Acta 2016, 202, 47–54.

Fig. 1. Silver structures prepared by electroless plating. (a) Island-like silver nanoparticle film. (b) Coarse silver thin film. (c) Shape-controlled silver thin film composed of plates. (d) Template-fabricated silver nanotube-nanowire assembly.

Powered by Eventact EMS