BENEFITS OF ADDITIVE MANUFACTURING FOR INDUSTRIAL DESIGN. NEW APPLICATIONS, TRENDS, LIMITATIONS

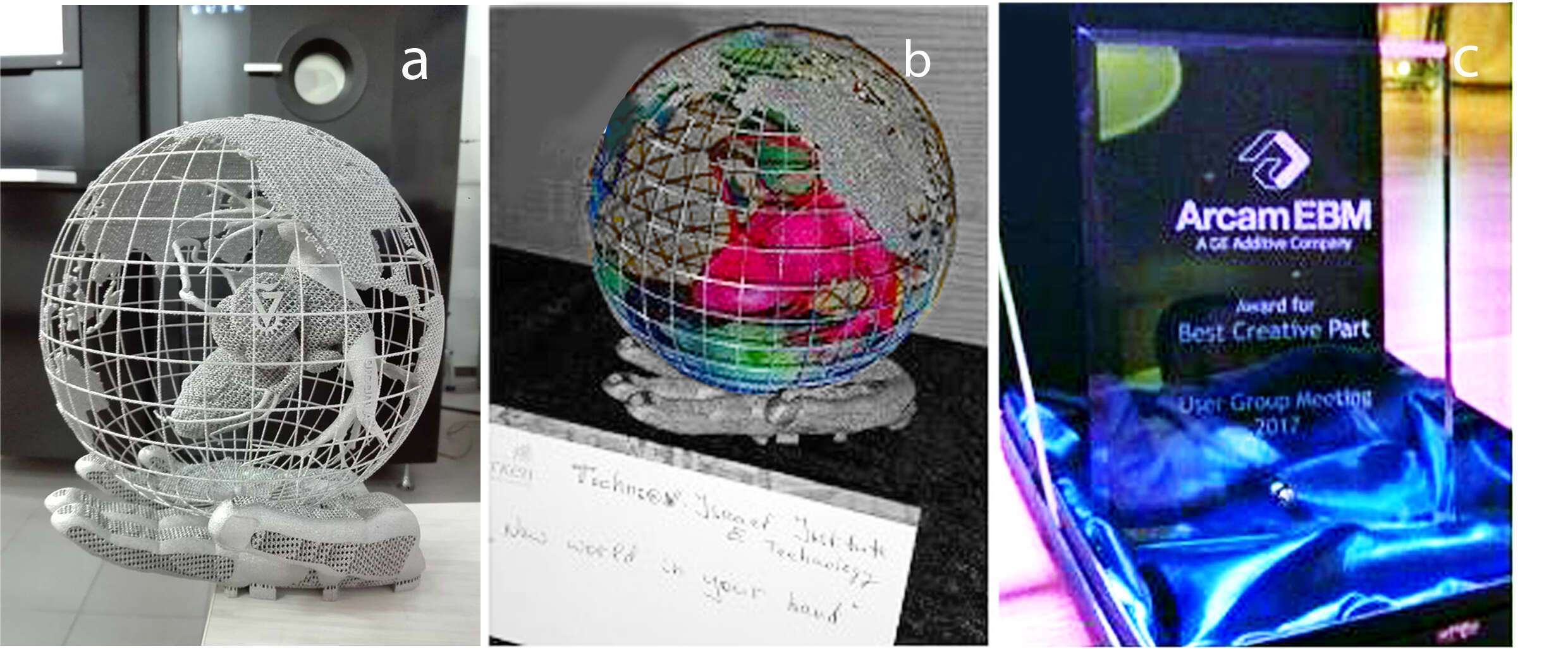

2Israel Institute of Metals, Technion-Israel Institute of Technology, Haifa, Israel

The work presents the use of the 3D-printing as a new effective instrument for industrial designers for developing new products and applications. The marketing prediction of the future development of titanium AM in industrial design is very positive. Today there are decades of 3D-machines producers, who provide different processes for different materials.

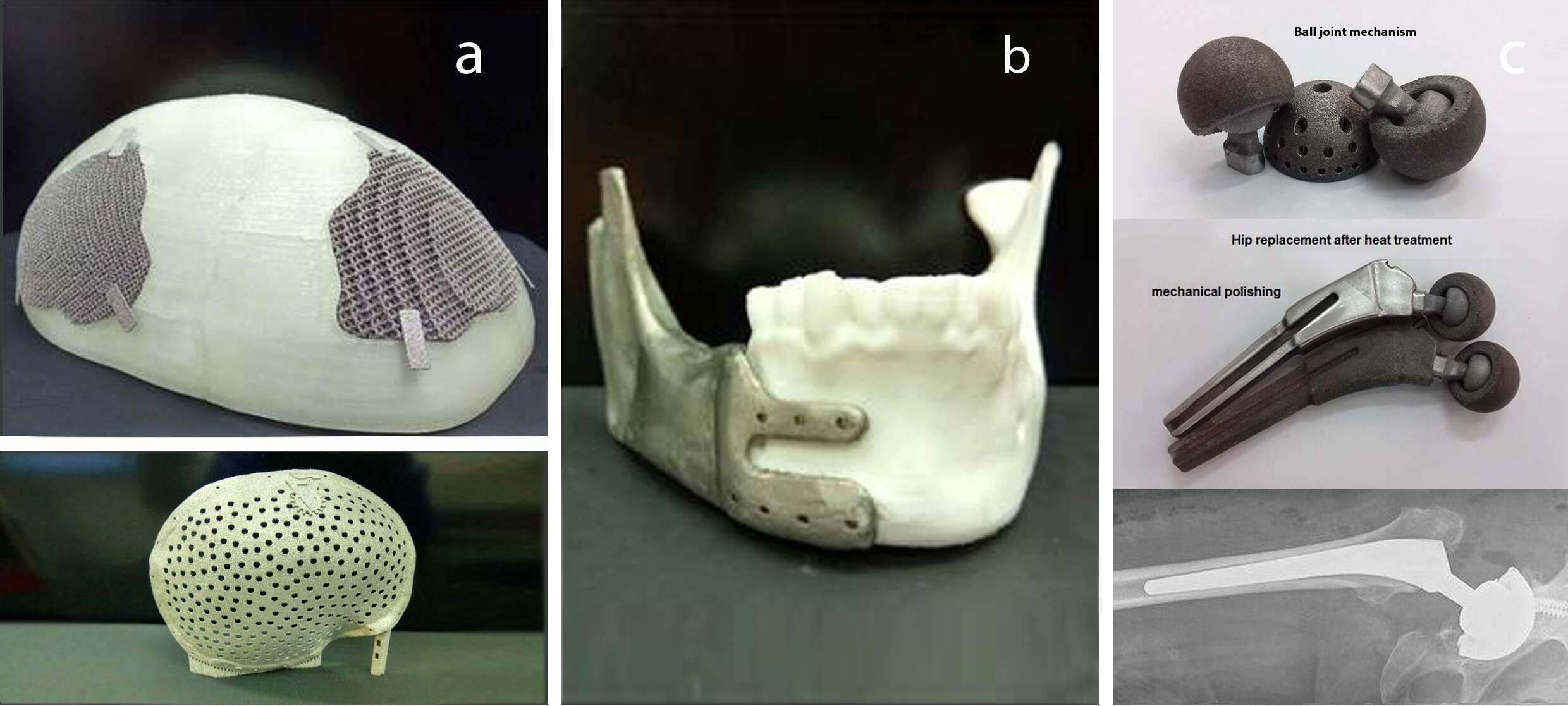

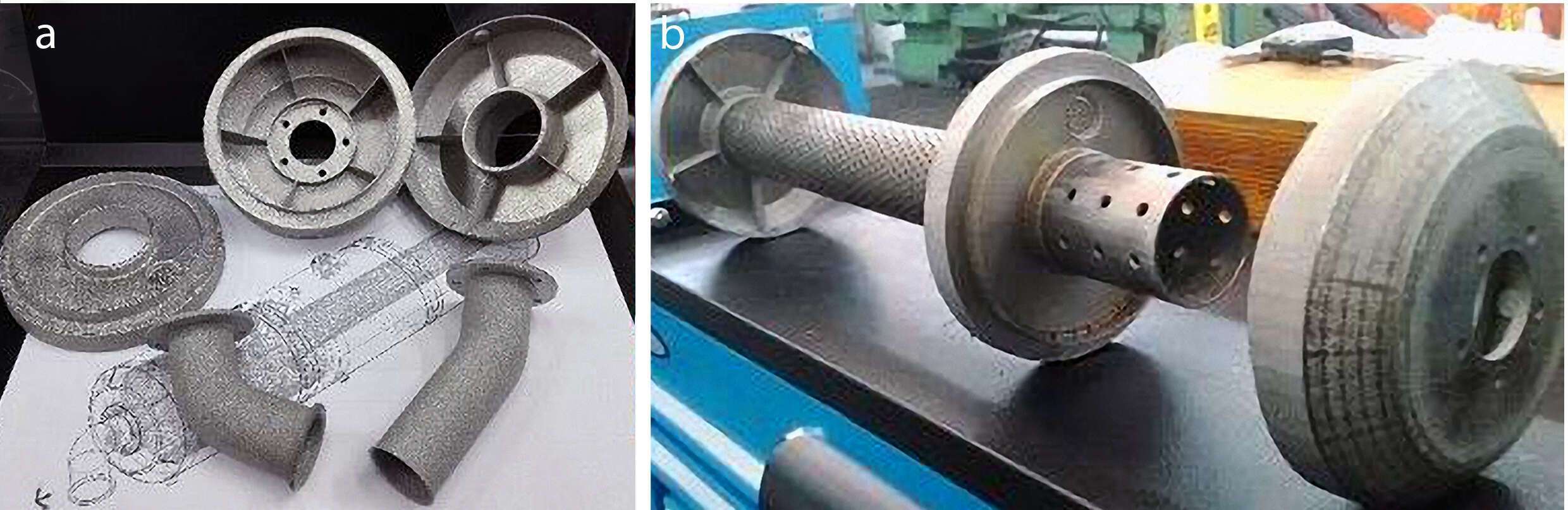

Titanium alloys, because of combination of light weight, ductility, high mechanical properties, fatigue resistance and corrosion resistance, provide interest to titanium 3D-printing not only for medical, aerospace, or automotive applications, but also for specific engineering systems, electronics, art and even for musical instruments.

Many researchers believe that additive manufacturing (AM) will shape the future of production and will stimulate new development in engineering and manufacturing processes. However it is already clear that AM could not replace traditional methods of production like casting at all. 3D printing has its own niche where it is uncompetitive: low-serial production of highly complicated geometrical lightweight parts. And first of all it is design and development of new products and applications. And here AM becomes an effective instrument for industrial designers for prototyping new products, and to develop them up to final net-shape products with specific mechanical properties.

Powered by Eventact EMS