FORMATION OF NANOPOROUS Au THIN FILM AND NANOWHISKERS BY PHYSICAL VAPOR DEPOSITION

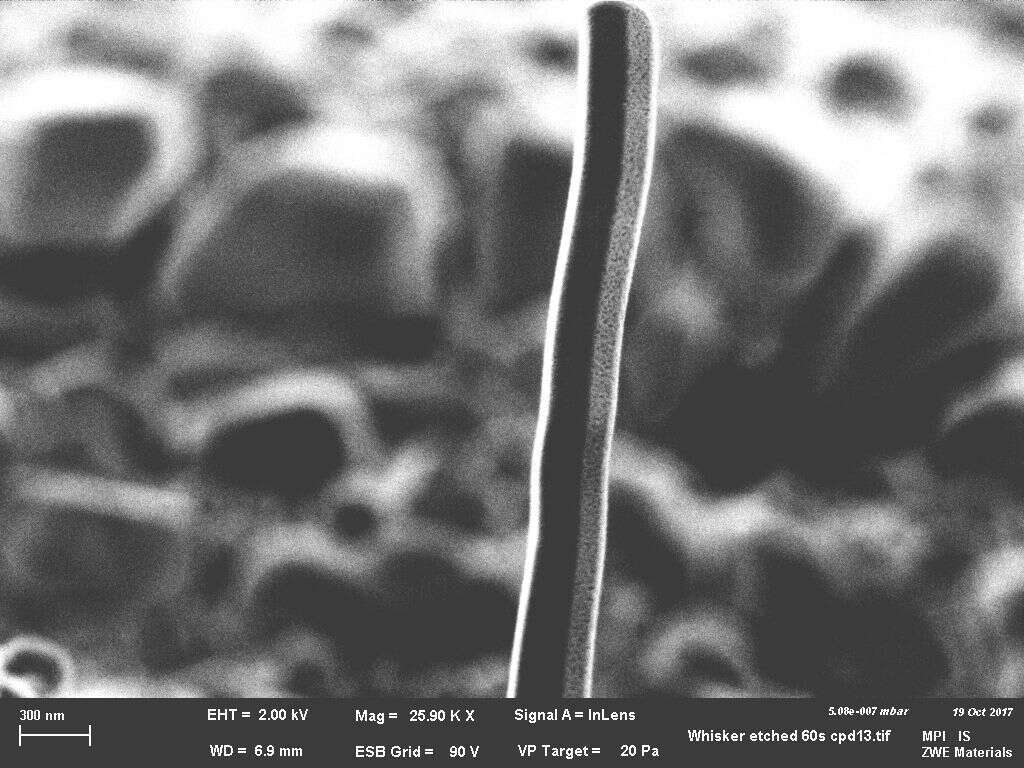

With decreasing dimensions, the physical properties of structures changes severely. This well-known effect is under investigation for e.g. mechanical, magnetic or electronic properties. To probe the genuine size effects of materials is of importance to separate these from the influences of microstructure defects, as grain boundary and interfaces, dislocations, or impurities. Tailored nanostructures are therefore needed to separate size from microstructural effects. Therefore, fabrication methods have to provide said tailored nanostructures. Semiconductor or ceramic nanowires are grown, e.g. via the vapor-liquid solid process; carbon nanotubes are synthesized via catalytic growth. Recently we reported a synthesis method for freestanding, defect free nanowhiskers by physical vapor deposition. Typical diameters are 100 nm, the length several micrometers. To reduce the governing dimensions of nanosystems even more introducing porosity is a well published method. In the presented work, we show the formation of nanoporous Au thin films and nanowhiskers. The first step is co-evaporation of Au-Ag alloy constituents from individual sources. Being a fully miscible material system, the composition of Au-Ag thin films and nanowhiskers can be controlled a wide range by tuning the deposition rates. Subsequent etching with nitric acid leads to nanoporous, Au rich thin films and nanowires. Depending on the etching conditions ligament and pore size can be controlled. Transmission electron microscopy and X-ray diffraction analysis show, that the microstructure, which was formed during deposition remains otherwise unchanged after etching. This process will lead to a further decrease of properties determining size in nanostructures.

Powered by Eventact EMS