COLUMNAR CRACKS CREATED DURING NANO PARTICLE JETTING (NPJ) PRINTING PROCESS

Nano particle jetting printing process consists of printing a sub-10 micron layer of ink, made out of solvent, dispersant and powder, on hot chuck. Most of the solvent is evaporated and then a new layer is printed. After the printing process ends, the part is inserted into a furnace to remove the solvent remains and the dispersant and to sinter the part to >95% density.

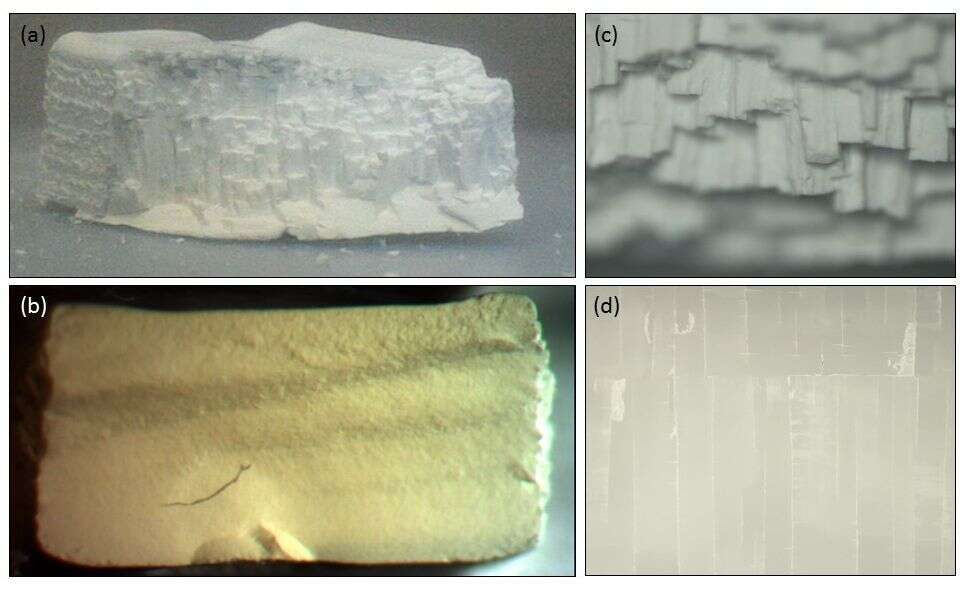

Cracks, created during the printing process have a distinct fracture surfaces of columnar cracks. Columnar cracks can be found in many places: pottery glazes, dried mud, end even the polar regions of the Earth and Mars. In all cases, the cracks evolve when a crack network opens and heals repeatedly, in a thin layer, or advances by many intermittent steps into a thick layer. The cracks in any cycle are guided by the positions of cracks in the previous cycle but when they can slightly vary their position and order of opening causing an intersection at 120° or Y-junctions.

The cracks formation and propagation in Xjet’s 3D printing process was studied, using metallographic and fractografic tests A solution was found using a heating and drying process. Green part 3 point bending tests were made to evaluate the increase in green part strength with reducing crack length.

a) Columnar cracks in green part

b) Mechanical crack in green part

c) Large magnification of columnar crack in green part

d) Polished cross section of sintered part

Powered by Eventact EMS