Advanced Electronics Platform Based on MCU for Nuclear Applications

2Electronics & Control Laboratories, Nuclear Research Center-Negev

Abstract

A major reduction in the size of scintillator base radiation detectors can be achieved by using a solid state based light sensor (SiPM) instead of the Photo Multiplier Tube (PMT) that is used traditionally for this application. While the SiPM is a thin device it also limited in light collection area. In order to par with the PMT in the light collection area it is possible to tile several SiPMs thus increasing the surface area without increasing the device thickness. The properties of each SiPM device are slightly different and in order to achieve optimal performances it is recommended to measure each SiPM separately, hence there is a need to develop a new general electronics platform that would enables to read concurrently several SiPM light sensors.

This paper presents the development of an electronic measurement platform that supports the entire feature set needed to collect data from an array of SiPM light sensors. The board platform detectors requirement like thresholds, adjustable Bias voltage 25V-35V and communication to PC. This platform is based on advanced MCU (Micro controller unit) 32 bit ARM Cortex-M4 with our developed electronic adjustment that has upgraded this board to high degree electro static discharge (ESD) required by the nuclear industry.

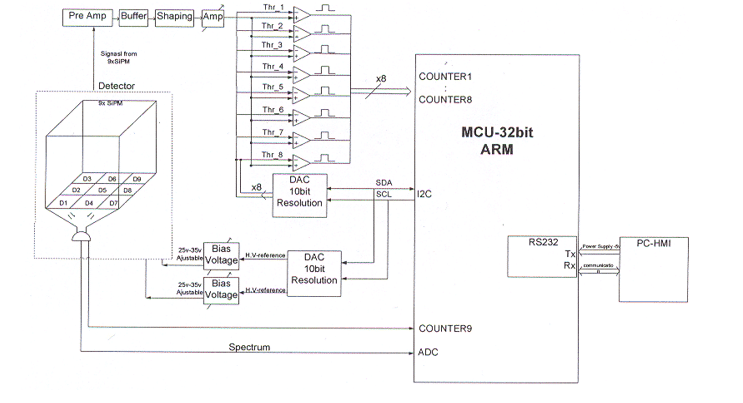

This electronic board can be connected to nine detectors, and can be used as a generic platform to a variety of nuclear application and lab tests. One of the most familiar applications is to find in high resolution direction of gamma radiation based on 9 SiPM detectors as shown in figure 1.

Figure 1: Schematic diagram of the electronic circuit with ability to communicate up to 9 different detectors

Electronic design and algorithm

The electronic design needs to support all nine sensor configuration base on SiPM technology. Dedicate pre-amplifier, shaping, amplifier was design to achieve unique properties such as: DC performance, Gain stability, infinite input and low output impedance. The electronic design includes a main board for providing bias voltage with temperature compensation to every diode, shape the collected signal and divide the signal in to several energy windows to achieve flat energy response. Every separated Signal from diode D1-D9 has individual adjustable low thresholds and can be path to 8 hardware counters the rest 1 signal will count in external interrupts pin by software in modern 32-bit MCU. The advantage of hardware counter compared with external interrupts count is the ability to count up to 4 Mcps against 80Kcps in external interrupts count. The electronic board includes an analog output signal that can path out the board by coaxial connector to make spectrometric measurement by external MCA.

To overcome an environment noise that is caused by high radiation or extreme weather we used in ESD components for all digital and analog I/O. To prevent interferences, caused by high radiation condition, to entering of undesirable pulses to the MCU counter`s in the last stage I comperes the TTL signal from detector with a constant DC voltage level. All these actions give stability to the board.

HMI with the board

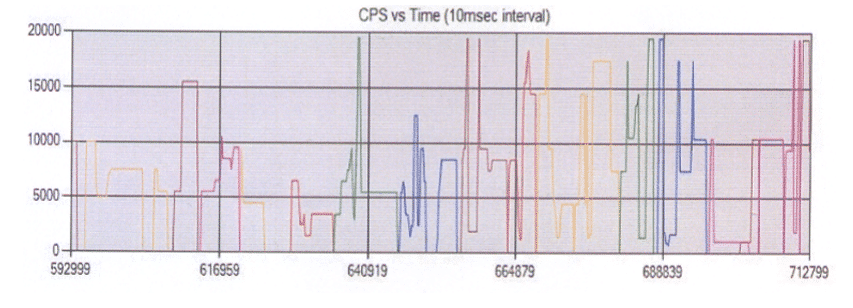

A unique PC HMI program made to communicate with this board and collect all the data from detectors. The HMI display in real time: the counters time graphs (figure 2), analog signals from ADC and digitals signal. The HMI can be updated in every 10 msec interval.

Figure 2: 7 counters

Figure 2 is an example of a real time counters graph from 7 counters. We can see that the TTL signal over the 7 counters. Each color indicates counts from different counter.

Powered by Eventact EMS