Strained Nanomechanical Resonators with Low Dissipation

2Quantum Technology & Computing, IBM Research

Ultralow dissipation mechanical resonators are an essential resource in the field of cavity optomechanics. We employ soft-clamping, elastic strain engineering and monocrystalline materials to enhance their quality factors to unprecedented values.

Force and displacement sensitivity of sensors based on mechanical resonators are fundamentally limited by thermal noise affecting resonator modes. As prescribed by the fluctuation-dissipation theorem, the thermal noise is lower in mechanical resonators with high quality factors (Q). Increasing Q is thus crucial for achieving high sensitivity. Moreover, the mechanical quality factor sets the limits of many experiments in cavity optomechanics, such as cooling the resonant mode to its ground state through feedback from the detected motion1,2.

The identification of loss dilution as a mechanism of dissipation suppression in micromechanical resonators under high tensile stress has broken a paradigm in which higher quality factors were associated with larger mechanical resonators. By contrast, loss dilution privileges structures with extreme geometric aspect ratios, commonly accessible through nanofabrication.

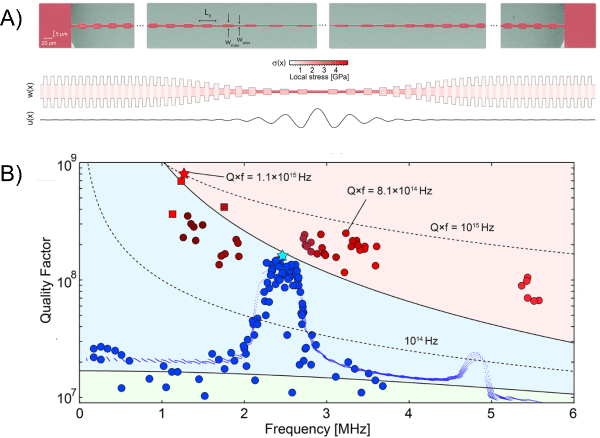

Employing localized resonant modes, shielded within a phononic crystal, elegantly enhances the loss dilution effect, by suppressing the dominant limitation to the diluted Q set by the extreme curvature established at the clamping points. For this reason, the technique has been termed soft clamping3.

We demonstrate how soft clamping can be combined with elastic strain engineering (ESE), further increasing the loss dilution by locally enhancing the material strain. ESE pushes the boundaries of Q and Q⋅f to a limit enforced by the material yield strain, rather than the process parameters of thin-film deposition. This concept can be applied to localized flexural modes in one- and two-dimensional suspended resonators. We achieved Q ≈ 8⋅108 and Q⋅f > 1015 with high aspect ratio nanobeams4.

A complementary technique to soft-clamping relies on engineering the geometry of the clamping points of a nanobeam: tapered clamps, with locally-enhanced stress, improve the quality factors of low-frequency modes and can be implemented without changing the device size5.

These design and fabrication techniques have been very successful in reducing mechanical dissipation, but have so far been applied mostly to silicon nitride, an amorphous solid. Single-crystal films of, e.g., III-V semiconductors or silicon, under appropriate conditions, exhibit a much higher intrinsic, undiluted Q. In these crystalline films strain is commonly introduced during epitaxial growth. Straightforwardly adapting the aforementioned techniques on crystalline resonators could lead to a new generation of ultracoherent devices, with Q ≈ 1010 at cryogenic temperatures.

References:

1. Wilson, D. J. et al., Nature (2015).

2. Rossi, M., Mason, D., Chen, J., Tsaturyan, Y. & Schliesser, A., arXiv e-print (2018).

3. Tsaturyan, Y., Barg, A., Polzik, E. S. & Schliesser, A., Nat. Nanotechnol. (2017).

4. Ghadimi, A. H. et al., Science (2018)

5. Bereyhi, M. J. et al., arXiv e-print (2018).

Powered by Eventact EMS