THREE-DIMENSIONAL AND SPATIALLY-CONTROLLED GROWTH OF METAL OXIDES IN BLOCK COPOLYMER TEMPLATES

Block copolymers (BCP) are known to spontaneously self-assemble into a variety of well-ordered nanostructures with feature size ranging between 5 and 50 nm, making them ideal materials for low-cost patterning. Combining BCP self-assembly with sequential infiltration synthesis (SIS), a novel technique for selectively growing inorganic materials within the polar domains of BCP from metalorganic gaseous precursor, leads to hybrid organic-inorganic nanostructures. Subsequent removal of the block copolymer film using oxygen plasma results in 3D inorganic nanostructure templated by the BCP structure, offering a new pathway for nanostructure fabrication. However, up until now, SIS-based nanostructure fabrication was limited to a single material at a time. Controlling SIS growth of multiple precursors will enable fabrication of spatially-controlled heterostructures.

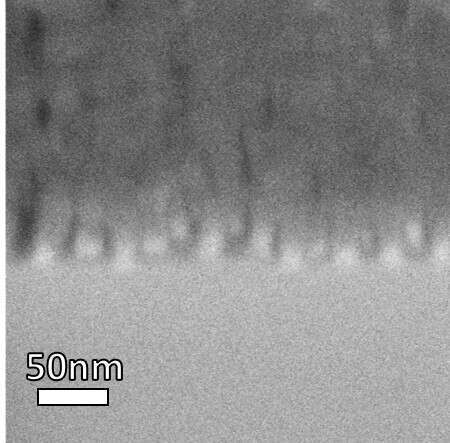

In this research, we harness the self-assembly of BCP to create film with 20 nm wide perpendicular cylinders that serve as a templating material. By tuning the SIS infiltration time, we gain control over the precursors’ infiltration and growth depth within the BCP cylindrical domains. The growth depth of DEZ (Diethyl zinc) and TMA (trimethyl aluminium) was tuned to form a combined heterostructure of Al2O3 and ZnO.

Structural characterization using scanning and transmission electron microscopy (SEM and TEM, respectively) was performed to characterize the metal oxide nanorods. Importantly, scanning TEM (STEM) tomography (Figure 2) and Energy-dispersive X-ray spectroscopy (EDS) STEM tomography were performed in order to precisely probe the 3D structure and the chemical composition of the heterostructure nanorods.

Figure 1: Cross section SEM of heterostructures cylinders with Al2O3 on top and ZnO on the bottom

Figure 2: Cross sectional view of the reconstructed volume obtained through STEM tomography

Powered by Eventact EMS