CHARACTERIZATION OF NANOSIZED PARTICLES IN 14%Cr OXIDE DISPERSION STRENGTHENED (ODS) STEEL USING CLASSICAL AND FRONTIER MICROSCOPY METHODS

2Institute for Theoretical and Experimental Physics named by A.I. Alikhanov of National Research Centre, Kurchatov Institute, Moscow, Russia

3National Research Nuclear University, MEPhI, Moscow, Russia

4., Nuclear Research Center-Negev, Beer sheva, Israel

Oxide dispersion strengthened (ODS) steels exhibit superior mechanical properties and irradiation resistance due to the nano-sized oxides, highly dispersed in metallic matrix [1, for example]. These properties change as a function of the structure, composition, size and density of the nano-sized oxides. Thus, characterization of these oxides is crucial. Despite the numerous reports on this subject, ambiguity remains. In the present study, characterization of the crystallographic structure of oxide particles existing in 14%Cr ODS steel was performed using classical and novel transmission electron microscopy (TEM) methods. 3D dispersion, density and composition of these oxides were evaluated by atom probe tomography (APT).

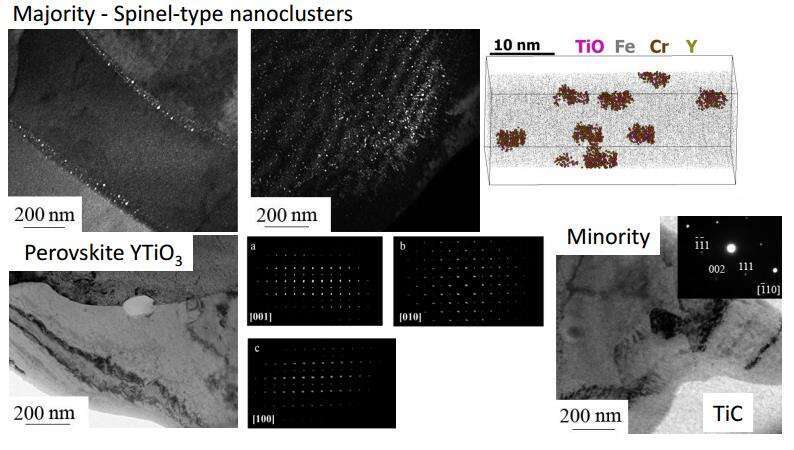

Nano-sized particles observed in the studied ODS steel varied greatly in size. It was possible to classify them into several populations. The largest particles in this steel were characterized using classical TEM methods as TiC (FCC) with a typical size of 100-150 nm. An example of such particle is shown in fig 1 (bottom right). This type of particles was the least frequent in the studied steel. Other large oxide particles with sizes of 50-150 nm belong to the second population, see fig 1 (bottom left). Energy Dispersive Spectroscopy (EDS) analysis preformed on these particles found that they are composed mainly of Y, Ti and O. The distribution of this type of particles was significantly higher than of TiC. In addition, dense distribution of nano-sized particles, varying from several to 20 nm, was observed in this steel. Due to their nanometric size, they were hard to detect on bright field (BF) TEM images. However, dark field (DF) images obtained from an extra (e.g. in addition to the Fe matrix) reflections in the electron diffraction (ED) pattern enabled to observe them very clearly, see fig 1 (upper panel). These nano-particles were sometimes observed at the grain boundaries, and sometimes in the grains’ interior, respectively. APT results allowed concluding that the nanosized oxides are composed of O, Fe, Ti, Cr and a negligible amount of Y.

Characterization of the crystallographic structure of both types of oxides was hindered due to the fact that Fe matrix also contributed to the ED patterns and, furthermore, there exist distinct orientation relationship (OR) between the oxides and the matrix. Thus, for their characterization extraction replica TEM sample was prepared to isolate the oxide particles. However, replica samples contained only the larger oxide particles. The crystallographic structure of the larger oxide particles was determined using electron diffraction tomography (EDT) method [2]. Following manual data collection, the frames were merged using the EDT-process software which enables to reconstruct a 3D projection of the reciprocal space. Following a successful reconstruction, a list of dhkl and intensities was extracted. The projections of the highest symmetry, i.e. [100], [010] and [001] are shown fig 1, bottom row. Their net symmetry was evaluated as 2mm. Thus, the crystal system was classified as orthorhombic and unit cell parameters were obtained. Analysis of the dataset intensities allowed deducing the following reflection conditions: h00 h=2n; 0k0 k=2n; 00l l=2n; hk0 h+k=2n; 0kl k+l=2n. These conditions belong to the Pn_n extinction (diffraction) symbol, i.e. Pn2n (34) or Pnmn (58) space groups. According to the PDF4+ (2018) database, the YTiO3 with a distorted perovskite structure exists with close to the obtained here lattice parameters and Pnmn space group. Thus, studied particles were attributed to this structure. In order to prove that the particles in the matrix had the same structure as those in the replica, ED patterns of the particles embedded in the matrix (e.g. original bulk TEM sample) were analyzed and successfully indexed in terms of the YTiO3 structure. It should be noted that in vast majority of the reports on ternary oxides in these steels other Y-Ti-O structures were noted, but the characterization was always ambiguous (e.g. one orientation ED and/or Fast Fourier Transform (FFT) of High resolution TEM). Here, the results were verified by two independent methods - zone axis ED patterns, taken from the bulk specimens and EDT data from the replica.

Smallest particles were very difficult to characterize. Their crystallographic structure was determined here using the superimposed matrix/oxide ED patterns. ED patterns taken from [100] and [110] orientations of the matrix contained diffused scattering and some extra spots originated by these nanoparticles. In the [111] orientation, however, no additional spots had appeared. These Fe ED patterns were found to be identical to the reported in literature superimposed ED patters of Fe and its native oxide films [3, for example]. In order to verify that in our case these oxides are not native, the samples were cleaned using precision ion polishing system before each TEM session. We have successfully indexed these patterns in terms of Fe,Cr,Ti-O oxides with MgAl2O4-type spinel structure having Bain and Kurdjumov-Sachs ORs for the [100]Fe and [100]Fe orientations, respectively. Spinel structure is rarely reported in the literature regarding ODS steels. In fact, we have found only one article [4], which had reported existence of spinel TiCr2O4 in ODS. Our case is different, since measured by APT composition is not TiCr2O4 and our particles exhibit unique nano-size and uniform distribution.

Correct and unambiguous characterization of nano-sized particles, attributing the strength to this ODS steel (which is potential candidate to be used as structural material in the IV generation nuclear reactors) – is a major breakthrough allowing full understanding of this steel`s properties.

Fig. 1: Upper panel: characterization of majority of particles. DF TEM images illustrate distribution of these particles in different grains. APT image shows their size and composition. Bottom panel: characterization of other particles as perovskite YTiO3 (with three major orientations taken from EDT data) and TiC.

References: 1. S. Ukai and M. Fujiwara, J. Nucl. Mater. 307–311, 749 (2002); 2. U. Kolb, T. Gorelik, C. Kübel, M. T. Otten, and D. Hubert, Ultramicroscopy 107, 507 (2007); 3. K. Kuroda, B. D. Cahan, and T. E. Mitchell, J. Electrochem. Soc. 129, 2163 (1982); 4. C. Lu, Z. Lu, R. Xie, C. Liu, and L. Wang, J. Nucl. Mater. 455, 366 (2014).

Powered by Eventact EMS