MICROSTRUCTURAL CHARACTERIZATION OF NOVEL AlCrFeNiNb0.3 HIGH ENTROPY ALLOY

2Negev, Nuclear Research Center, Beer Sheva, Israel

High entropy alloys (HEA) present novel metallurgical approach. Instead of commonly used alloying of one major constituent, in HEAs – 4-6 principal elements are used with a concentration of 5¸35at.% yielding a solid solution. HEAs exhibit unique combinations of good mechanical properties, high temperature durability, wear and oxidation resistance. AlCrFeNi- based HEAs are the most studied alloys. AlCrFeNi is bcc solid solution, possessing high strength with relative large ductility. It was found that addition of 0.3-0.5 at.% of Ti or Mo causes tremendously strengthening without causing a serious embrittlement. Since in other systems, addition of Nb has the same effect, novel - AlCrFeNiNb0.3 HEA was cast in this research. Combining X-ray diffraction, scanning electron microscopy (SEM) and transmission electron microscopy (TEM) analyses, microstructure and the solidification path was studied. Fig. 1 represents complicated microstructure of studied alloy.

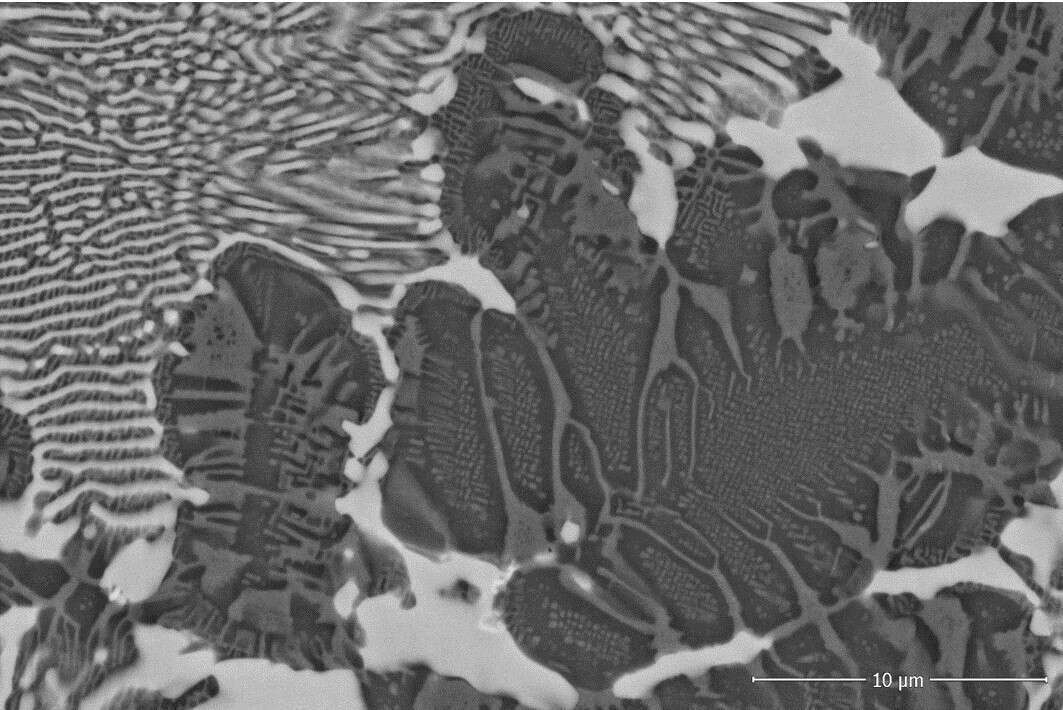

Figure 1: SEM image showing complex microstructure of the AlCrFeNiNb0.3 HEA

It was found that AlCrFeNiNb0.3 solidifies dendritically. The dendrite (DR) core is comprised of alternating bcc/B2 matrix and particles. Interdendrite (ID) region is composed of Laves phase, bcc and network of B2 particles. Unexpectedly, some intermetalides with the TiAl3 structure type were detected in this alloy. These particles exhibited high density of structural defects. Furthermore, the symmetry of theses intermetallides has changed depending on their location, e.g. in the particles` interior or in the matrix grains.

Powered by Eventact EMS