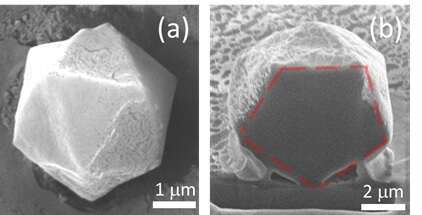

COLLOIDAL ICOSAHEDRA AND OTHER POLYHEDRA: FROM SYNTHESIS TO CROSS-SECTIONAL ELECTRON MICROSCOPY IMAGING

2Chemistry, Bar Ilan University, Ramat Gan, Israel

3Institute of Nanotechnology and Advanced Materials, Bar Ilan University, Ramat Gan, Ramat Gan, Israel

KEY WORDS: scanning electron microscopy, focused ion beam, colloids, icosahedra, polyhedra, interfacial freezing, surfactant-stabilized emulsions.

Colloidal suspensions have widespread applications in science and technology. Their properties depend on the shape of the constituent colloidal particles. Although promising for many applications in science and technology, polymeric colloidal icosahedra have never been formed. Moreover, no icosahedral particles of any material could be formed in the size range between 400 nm and the 3D printing resolution limit (~20 mm).

We demonstrate a new strategy, to form icosahedral polymeric particles in a wide range of sizes, from sub-mm to ~100 nm, based on our recent observations of temperature-tunable shape transitions in liquid droplets. Surfactant-stabilized droplets of oil in water, transform from a spherical shape into sharp-edged faceted polyhedra, dictated by the molecular-level topology of their closed surface, by surface-elasticity, and by their surface tension1. The transformation owes to a unique interfacial freezing transition, where a 2-nm-thick interfacial monolayer, composed of alkane and surfactant molecules, crystallizes at the surface of alkane-in-water surfactant-stabilized emulsion droplets at T=Ts. It coexists unchanged, with the liquid bulk phase of the droplets over a wide temperature range. At Td

We have successfully polymerized the droplets3, allowing us to study these droplets by means of a high resolution electron microscopy. To achieve polymerization, the alkane is replaced by polymerizable oil and a photoinitiator, allowing the droplets to become UV-polymerized. We employ a combination of focused ion beam and scanning electron microscopy methods, to determine the three-dimensional shape and internal structure of the polymerized droplets with a nanoscale resolution, shedding light onto the mechanisms of faceting in liquid droplets3. In addition to its fundamental importance, our method also opens the route towards mass production of complex-shape micron- and nano- building blocks for future metamaterials.

- S. Guttman et al., PNAS 113, 493 (2016).

- Denkov et al., Nature 528, 392 (2015).

- O. Marin et al., J. Colloid Interface Sci. 538, 541 (2019).

Powered by Eventact EMS