CONTROLLING THE THREE-DIMENSIONAL STRUCTURE OF METAL OXIDE ULTRAFILTRATION MEMBRANES THROUGH BLOCK COPOLYMER SELF-ASSEMBLY

2Faculty of Chemical Engineering, Technion – Israel Institute of Technology, Haifa, Israel

Block copolymers (BCPs) are considered promising materials for various membrane applications ranging from ultra-filtration for water treatment to protein separation due to their ability to self-assemble into highly ordered structures with uniform pore size and high pore density. Typically, the pore’s size and surface interactions are controlled by the BCP chemistry. However, simultaneous control over both properties is difficult to achieve. In particular, controlling the three dimensional (3D) structure of the pores through the BCP chemistry is considered a major challenge.

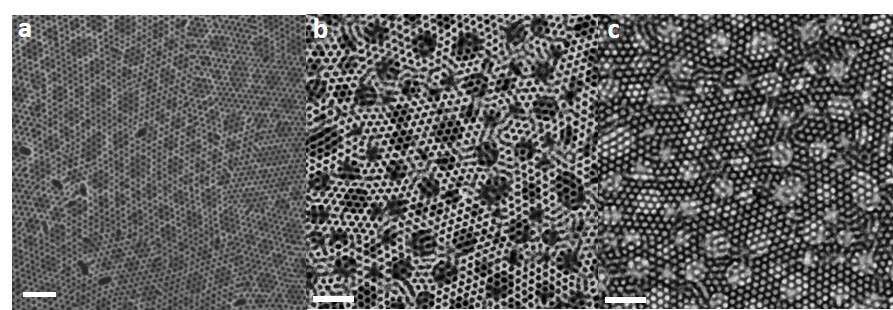

In this study, we aim to tailor the 3D structure of ultrafiltration membranes by precise layer-by-layer fabrication of block copolymer-templated metal oxide porous layers. Poly (styrene-block-methyl methacrylate) (PS-b-PMMA) and poly (styrene-b-2-vinyl pyridine) (PS-b-P2VP) were used to create BCP films with vertically-oriented polystyrene cylinders. Sequential infiltration synthesis (SIS), an atomic layer deposition based technique that enables selective growth of metal oxides inside the polar domains of BCP, was used to grow Al2O3 inside the PMMA and P2VP domains of the BCP films. The metal oxide growth was followed by polymer etching, resulting in block copolymer-templated metal oxide porous structure. Structural characterization was performed by scanning electron microscopy (SEM) (figure 1a) to probe the surface structure and analyze the resulting membrane pore size distribution. The double layered structure was imaged by scanning transmission electron microscopy (STEM) to visualize the 3-D pore structure by using high angle annular dark field (HAADF) (figure 1b) and bright field (BF) (figure 1c) STEM tomography. The judicious selection of the BCPs molecular weights and SIS processing conditions enabled us to separately tune the pore size of each layer. This layer-by-layer technique will allow control over pore size as well as surface chemistry, providing tools for fabricating efficient membranes for separation.

Figure 1 – Micrographs of a double layered aluminum oxide membrane from a) SEM b) HAADF STEM c) BF STEM

Powered by Eventact EMS