High-quality CuBi2O4 photoelectrodes with increased stability by rapid thermal processing of Bi2O3/CuO grown by pulsed laser deposition

2Institute Silicon Photovoltaics, Helmholtz-Zentrum Berlin Für Materialien Und Energie, Berlin, Germany

3Department of Structure and Dynamics of Energy Materials, Helmholtz-Zentrum Berlin Für Materialien Und Energie, Berlin, Germany

4Institute Quantum Phenomena in Novel Materials, Helmholtz-Zentrum Berlin Für Materialien Und Energie, Berlin, Germany

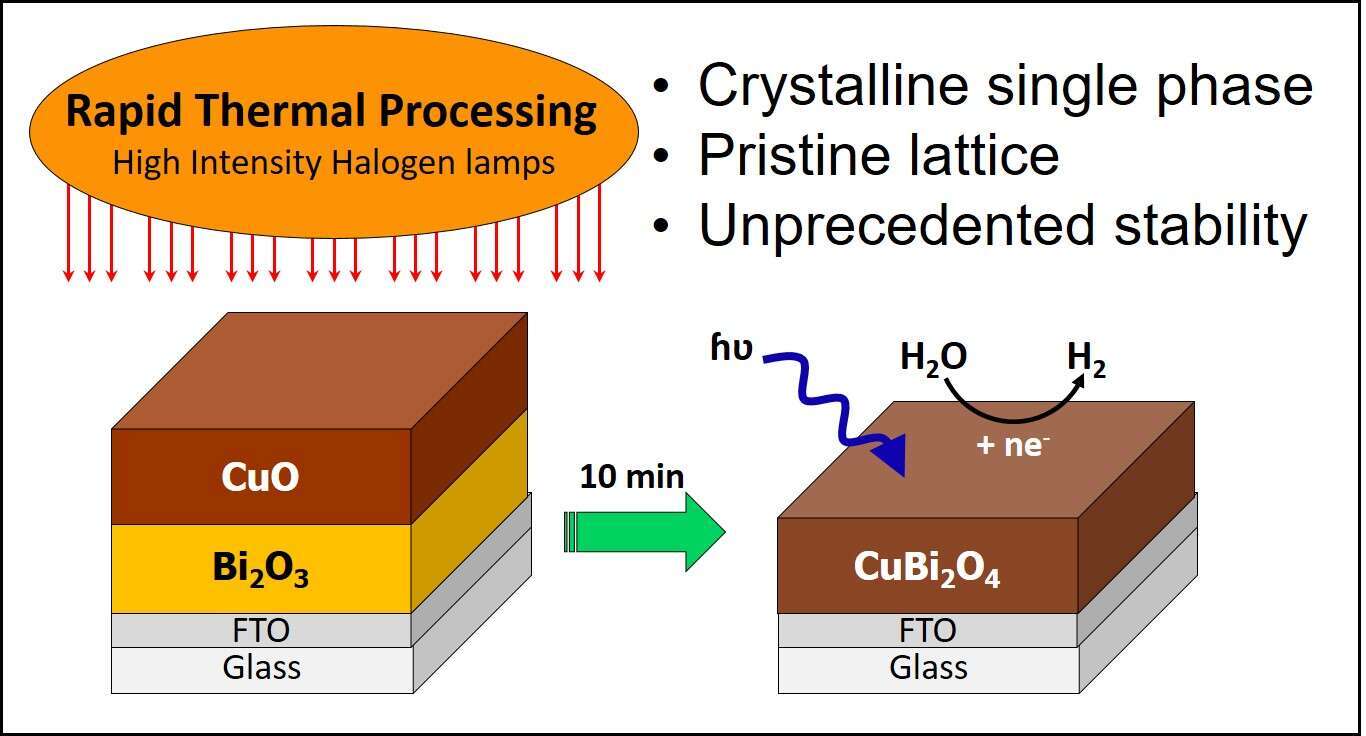

A new approach for fabricating high-quality ternary photoelectrodes such as CuBi2O4 (an emerging p-type semiconductor for solar hydrogen production) will be presented. Pulsed laser deposition (PLD) is used to deposit the binary oxides Bi2O3 and CuO on FTO substrates, and rapid thermal processing (RTP) is used to achieve an efficient solid-state reaction between the two oxide films. It is shown that when Bi2O3 is deposited first, the thin film photoelectrodes are comprised of single-phase, compact, crystalline, and well-defined CuBi2O4 particles. A comparative study with conventional furnace heating reveals the significance of radiative heating in the processing of complex metal oxides photoelectrodes. Additionally, the much shorter heating times enable the use of FTO substrates at temperatures up to 650 °C, higher than their thermal stability, also resulting in a low thermal budget (the product of process temperature and processing duration at elevated temperatures). In a comparative study with CuBi2O4 photoelectrodes produced by spray-pyrolysis, a benchmark synthesis technique of photoactive materials and complex metal-oxide photoelectrodes, the CuBi2O4 layer fabricated by PLD + RTP photoelectrodes featured superior electronic properties, which were sustained even in cases of a secondary oxide co-existence in the film by deliberately altering the Bi:Cu stoichiometry ratio during the PLD stage. The photoelectrodes have shown an efficient charge separation, low tail energies, and band-gap energy virtually identical to that of a CuBi2O4 single crystal, shown by modulated surface photovoltage analysis and confocal Raman microscopy. Furthermore, bare photoelectrodes, without the addition of electron scavengers, protection layers, or catalysts, exhibited exceptional photoelectrochemical stability, substantially improving the prospects of implementing CuBi2O4 photoelectrodes in photoelectrochemical devices towards high solar-to-hydrogen efficiencies.

Powered by Eventact EMS