Polymer degredation of polyethylene-terephthalate and nylon-6 in subcritical water as a novel strategy for upcycling of plastic waste

2Faculty of Civil and Environmental Engineering, Technion Israel Institute of Technology, Israel

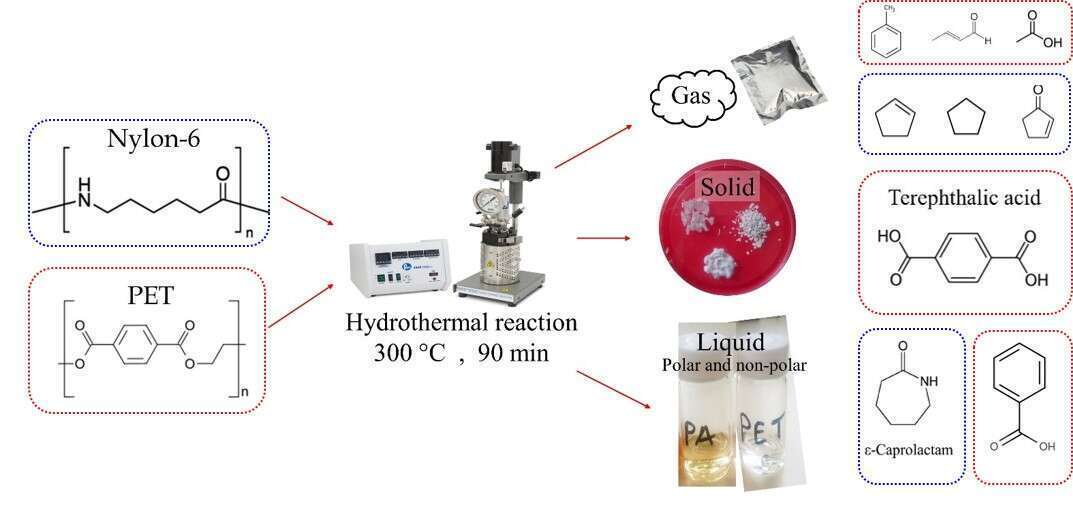

Increasing amount of post-consumer plastic waste creates a global pressure to move towards a circular plastic economy. Sustainable production and recycling processes for plastics are challenged mostly by the lack of renewable building blocks. This study investigates the hydrothermal processing (HTP) as a platform for depolymerization of two commonly used polymers. Subcritical water (300°C; 10 MPa) was tested as a solvent while polyethylene terephthalate (PET) and nylon-6 were treated individually and in a mixture for a short reaction time of 90 min. Monomer recovery and cross-interactions between the polymers were evaluated by a comprehensive identification of solid, liquid and gas products. Terephthalic acid (TPA), one of two monomers of PET was recovered as a solid product in mass yield of 75%. ε-caprolactam (CPL), the single monomer of nylon-6 was recovered as a liquid product in mass yield of 92.5%. Since those two monomeric products were recovered at different phases, an easy separation can be established while co-processing. Chemical depolymerization of mixed plastic waste by HTP can therefore contribute to a circular plastic economy and a more sustainable future.

Powered by Eventact EMS