Currently, the monosaccharide, glucose, is employed as a starting material for the production of several fuels and fine chemicals. Glucose is the sugar that could be easily fermented by yeast to produce ethanol. The focus of the current investigation is to identify the feasibility of using glycogen as a renewable feedstock for glucose production [1].

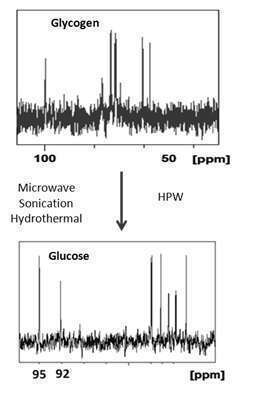

Complete conversion of glycogen to glucose is achieved by using HPW12O40·nH2O (HPW) and H4SiW12O45·nH2O (HSiW) as catalysts under optimized hydrothermal conditions (2.5 wt.% catalyst, 100 °C and 2 h reaction time) (Fig. 1).

Fig. 1. Methods for the conversion of glycogen to glucose

The reusability of the catalyst (HPW) has been demonstrated. In addition to carrying out the glycogen hydrolysis reaction in an autoclave, other novel methods such as microwave irradiation and sonication have also been investigated. At higher concentrations of the heteropoly acids (HPA's) (12 wt.%), glycogen could be completely converted to glucose under microwave irradiation. Sonication of an aqueous solution of glycogen in the presence of HPA's also yielded glucose. The progress of the hydrolysis reaction was monitored by13C NMR. HPA's were found to be efficient, environmentally friendly and reusable, for the conversion of glycogen to glucose. Glycogen can indeed be the renewable feedstock for glucose provided a chemical/biological methodology is developed for its bulk production using either CO2or some other inexpensive carbon source.

Reference:

|

1 |

Miri Klein, Indra Neel Pulidindi, Nina Perkas, Ella Meltzer-Mats, Arie Gruzman and Aharon Gedanken, RSC Advances, 2012, 2, 7262-7267. |