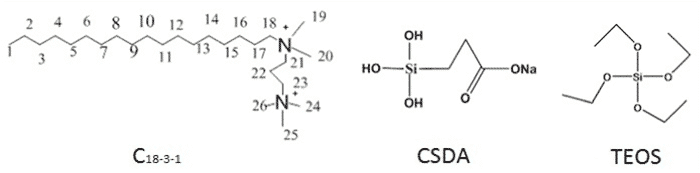

We aim at obtaining a molecular understanding for the mechanism responsible for the formation of mesoporous silica functionalized with carboxylic groups1. The materials are synthesized under aqueous conditions using a cationic surfactant (C18-3-1) as structure director, a co-structure directing agent (CSDA) and with tetraethylorthosilicate (TEOS) as silica source. The structures of the materials are dependent on the amount of HCl added in the synthesis. With increasing amount of HCl the structure transforms from (pH about 9) Fm-3m structure, to Fd-3m structure (pH about 6) 2. The silica network forms in a polymerisation reaction involving siliceous species, obtained after TEOS hydrolysis (producing siliceous species and ethanol), and the siliceous part of CSDA. The formation of the mesoporous structures rely on the self-assembly of the surfactant micelles and the silica network/species.

We have investigated the structural effect of TEOS hydrolysis. In two separate investigations we have either promoted the hydrolysis step, by introducing a pre-hydrolysis step, or slowed down the kinetics by addition of ethanol to the synthesis solution.

We conclude that the formation process is more complicated than has been postulated1. Pre-hydrolysis of TEOS results in the Fm-3m structure regardless of pH. When the hydrolysis is slowed down, by the addition of ethanol, the Fd-3m structure is more easily obtained. Hence, the hydrolysis rate is the important structural control parameter.

[1] Han, L. et al. J. Mater. Chem. 2007, 17, 1216-1221.

[2] Y. Sakamoto, et al. Chem. Mater., 2009, 21, 223-229.