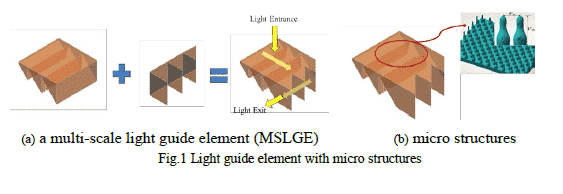

This paper is developed an injection molding process for a multi-scale light guide elements (MSLGE) for an opto-mechatronic system of in-door sunlight guiding and illumination application as shown in Fig.1a. A light guide element of prism has been designed with micro structures generated by the porous anodic alumina (PAA) template shown in Fig.1b. Simulation analysis of flow front has been executed with specific injection parameters setting and then compared with short-shot experiment of injection molding. Fig.2 shows related results with simulation and experiment. Packing and cooling analysis for shrinkage is shown in Fig.3 and the molding process of MSLGE has been developed to fabricate the marco-scale form of such prism and micro-scale SWAR structures by the developed injection molding process. The MSLGE of prism has been verified by optical measurement for its optical performance and discussed with related injection parameter setting. Results of this study can be adopted for future fabrication of structured prism with micro or nano anti-reflection application.

Keywords:multi-scale light guide element, injection molding, porous anodic alumina, sunlight illumination