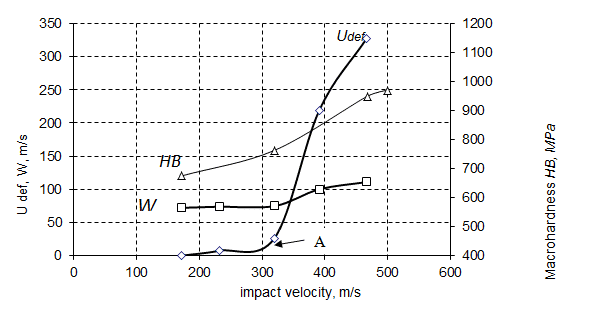

Despite extensive research work on shock deforming of copper, some aspects of shock-induced structure formation in this material remain largely unknown. Specifically, it concerns to nucleation of localized structures at the mesoscale [1,2]. After shock loading within narrow strain rate region of 5∙106÷5.7∙106 s-1 in M3 copper (grain size of 150÷350 µm) the chaotically distributed 3D-formations of 5÷30 µm in diameter have been found to be nucleated. The number of 3D- structures in single grain riches the value of 100÷300 units. Registration of free surface velocity by using velocity interferometry shows that nucleation of 3D-structures occurs at the strain rate when a valuable defect of particle velocity at the plateau of compressive pulse emerges. Higher impact velocity of 310÷320 m/s, dependence of velocity defect suffers a break which evidences a growth of energy expenditures on structure formation (Fig. 1).

Fig. 1. Dependencies of velocity defect, Udef, pull-back velocity, W, and HB-hardness on the impact velocity. Symbol A indicates transition to regime of fast growth of the velocity defect.

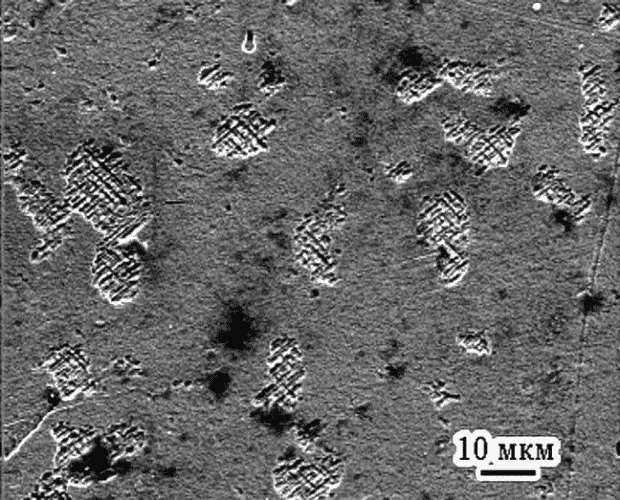

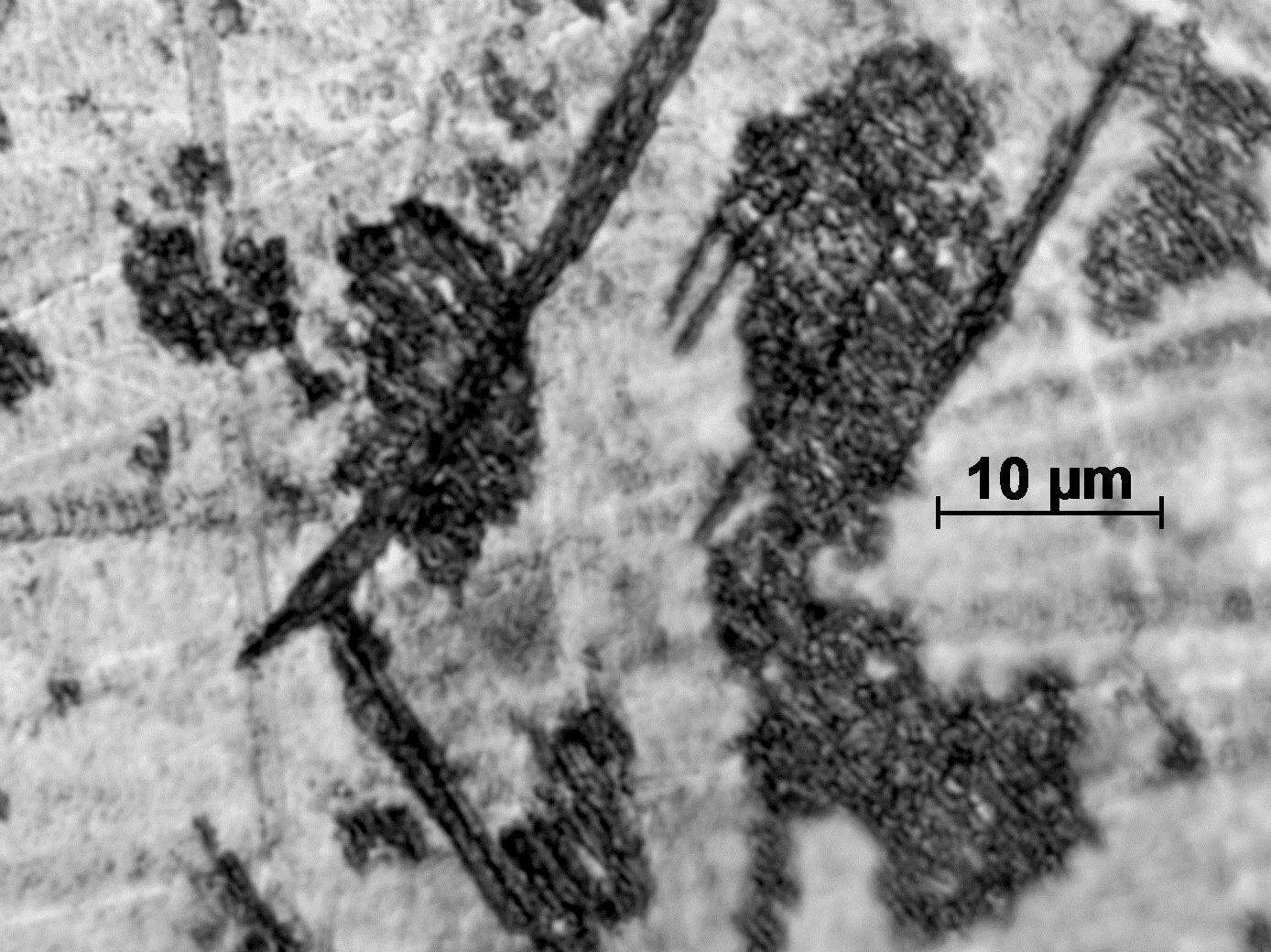

Morphological features of 3D-structures indicate on crystallographic mechanism of nucleation whereas a positive correlation between dimensions of structures and impact velocity allows to consider them as “domains of localized deformation” or 3D-structures (Fig.2).

Fig. 2. Shock-induced 3D-structures after passage of release wave in SEM and TEM microscopy

To reveal the mechanism of nucleation of shock-induced 3D-structures, metallographic examination of the recovered samples have been conducted by using SEM and TEM microscopy. 3D-structures turn out to be the three-dimensional nets which are formed by shear bands spaced by distance of 50÷100 nm (Fig.2).

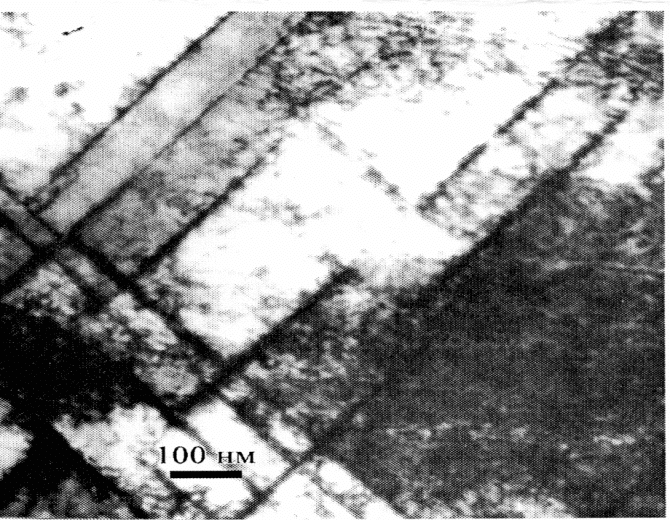

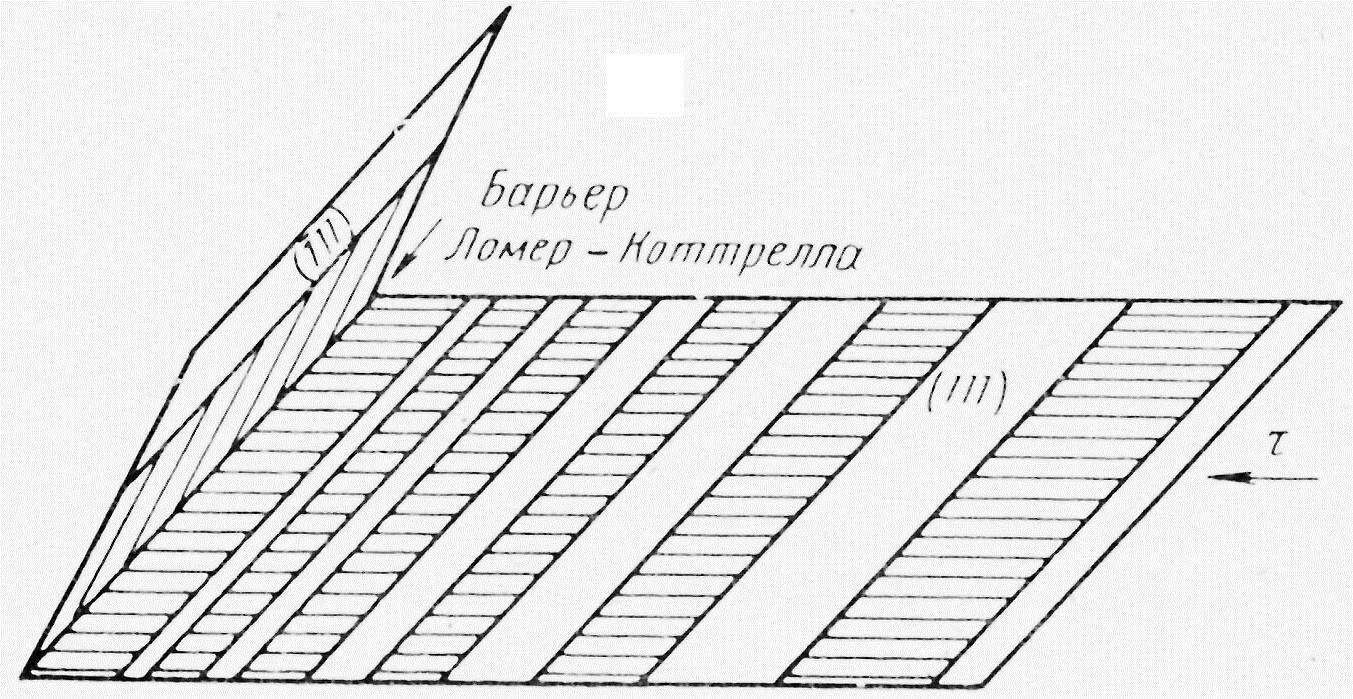

The shear bands are found to lie in the {111} plane system and are the set of Shockley partials linked with stocking faults. Such a kind of crystalline defects in fcc-lattice may slide in {111} planes in direction. On the basis of obtained data, a following consecutive order of shock-induced structural changes in copper may be suggested. Under conditions of shock loading, during the first passage of compressive wave, a high density of partial dislocations separated with stocking faults are nucleated. During the following passage of release wave, dislocation structure relaxes owing to motion of partial dislocations nucleated at the first passage of shock wave. Herewith, within the cross-sections of planes of sliding, the new defects are formed – Lomer-Cottrell dislocations [3-5] (see Fig.3a). They play a role of barriers for sliding the partial dislocations and just the Lomer-Cottrell barriers provide a hardening effect during the passage of release wave (see Fig.1). Thus, multilayer structures consisting of piles of frozen partial dislocations with stocking faults and Lomer-Cottrell barriers form the “domains of localized deformation” [6].

Chaotic distribution of deformation domains (Fig.1a) is a sequence of random positions of stacking faults resulting from the stochastic pulsations of mass velocity. The pulsation regime is initiated at the critical value of strain rate. It is characterized by fast growth of particle velocity variation and mass velocity defect (Fig.1). The mass velocity variation is considered to be a quantitative characteristic of the velocity pulsations. According to shock-wave experiments [1,2] the mean velocity variation in copper equals to ~ 50 m/s. This corresponds to local stress created by individual pulsation to be ~ 1.0 GPа. On the order hand, the lower limit of shear stress required by the stacking fault source for its action is close to the material elastic limit [7]. In the case of copper, it equals to 0.9 GPa, which is comparable to the local stress initiated by individual pulsation. Owing to mass velocity pulsations, during the first passage of shock wave the chaotically distributed stocking faults are intensively nucleated. During the release wave, the partial dislocations together with Lomer-Cottrell barriers form the three-dimensional frameworks of shear bands. As a result, the material presents a composite consisting of matrix and chaotically distributed 3D-formations “frozen” into crystalline lattice. The following deformation processes cannot change their morphology. This is clearly seen in Fig. 3b where shear bands cross the 3D-formations.

- b)

Fig.3. a). Lomer-Cottrell barrier; b) Intersection of shear bands and 3D- structure in copper

Above scheme of structural changes occurring in shock loading of fcc-crystals doesn’t contradict to experimental data of [8] obtained with X-ray monitoring in real time. It has been shown that during the shock deforming of fcc-crystals, the shear deformation is realized mainly by means of nucleation and growth of stocking faults. This point also agrees with the results of MD-modeling which also shows that stocking faults are chaotically nucleated even at earlier stages of high-velocity straining [9].

References

- Yu.I. Meshcheryakov, A.K. Divakov, N.I. Zhigacheva, S.V. Razorenov. “Turbulization of Dynamic Straining”. Proceeding of Intern. Conference” Shock Waves in Condensed Matter”-2006, Saint-Petersburg, 3-8 September. High-Pressure Center Publishing, Moscow, pp 196-201.

- Yu.I. Meshcheryakov, A.K. Divakov, N.I. Zhigacheva, I.P. Makarevich, B.K. Barakhtin. Dynamic structures in shock-loaded copper. Phys. Rev. B.Vol.78, pp. 64301-64316, (2008).

- I.I. Novikov. Defects of crystalline lattice of М.: Меtallurgy, 1975. 208 p.

- Coujou A. Acta Met. V.31,№10.- С.1505. (1983).

- Rayan K. Scripta Met. V.17,№1.- С.101. (1983).

- V.F. Moiseev, V.I. Trefilov. Deposit of twinning into plastic deformation of polycrystals.

Physical nature of plastic deformation and fracture of materials. – Кiew: Naukova Dumka,.

- 7-11 (1969).

- E.B. Zaretsky. Dislocation multiplication behind the shock front. J/ Appl. Phys. 78, No 6,

- 3740-3747 (1995).

- E.B. Zaretsky, G.I. Kanel, M.A. Mogilevsky, and V.E. Fortov. Нigh Temperature Physics.

- 29, p.1002 (1991).

- M.A. Mogilevsky. In; “Shock Waves and High Strain Rate Phenomena in Metals”.

Editors: M.A. Meyers and L.E. Murr. Plenum Press, N.Y. pp. 531-542, (1981).