A novel pressure-sensitive luminescent coating for microscale flow visualization.

Pressure-sensitive paint (PSP) technique has been widely acknowledged as a promising tool to visualize surface pressure distributions with high spatial resolution [1]. PSP is an optical imaging sensor for measuring surface pressure based on the oxygen quenching of photoluminescence. Conventional PSP is composed of luminescent dyes and oxygen-permeable polymer, which immobilizes the dyes on solid surfaces. When PSP is exposed to light with appropriate wavelengths to excite the electronic states of the dyes in the paint, the dyes absorb the energy of the photons and then emit luminescence. The intensity of the luminescence depends on the partial pressure of oxygen related to the local static pressure of air at the surface of the paint due to the oxygen quenching. Thus, surface pressure distributions can be obtained from intensity distributions acquired by imaging sensors such as charge-coupled device (CCD) cameras.

One of the most prominent features of the PSP technique is that the probes (i.e., luminescent dyes) are extremely small compared with those of other conventional pressure measurement tools. Therefore, it has been expected that the PSP can be used for pressure measurements in micro-scale flow devices. Huang et al. [2] and Nagai et al. [3] have applied the PSP technique to visualize surface pressure distributions in de Laval nozzles with throats of sub-millimeter scales. Although they successfully demonstrated the possibility of the PSP technique for the visualization of pressure distributions in micro-scale channels, conventional, polymer-based PSPs used in their works have inherent limitations on the controllability of thickness and surface roughness. In order to apply the PSP technique to flows with much smaller scales, it is essential to develop alternative methods to immobilize the luminescent dyes on the surface of the flow channels more uniformly.

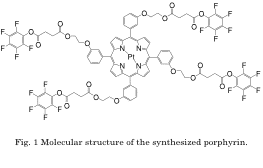

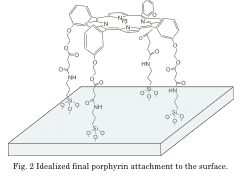

In the present work, we have developed a novel pressure-sensitive luminescent coating (PSLC) applicable to the visualization of pressure distributions in micro-scale flow devices based on the self-assembled monolayer (SAM) technique [4]. The SAMs are molecular assemblies that are formed spontaneously by the immersion of an appropriate substrate into the solution of active molecules in an organic solvent. We synthesized a porphyrin, Pt(II)-tetra[3-(pentafluorophenoxysuccinyl-oxyethoxy)phenyl]-porphyrin (PtTPFPSOPP) based on previously described procedures [5, 6]. The molecular structure of the porphyrin is shown in Fig. 1. Porphyrin self-assembling on indium tin oxide (ITO) glass plates was achieved in two successive steps: the first step was the surface activation by 3-aminopropyltrimethoxysilane (APTMS) and the second was the amidation reaction resulting in the formation of the porphyrin SAM [7]. The idealized final porphyrin attachment to the surface is shown in Fig. 2.

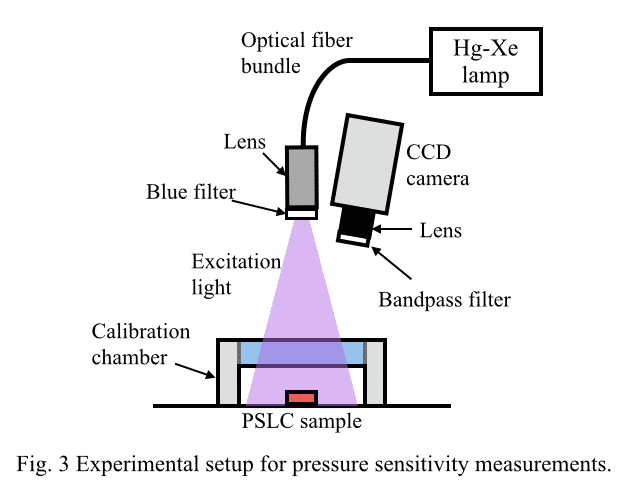

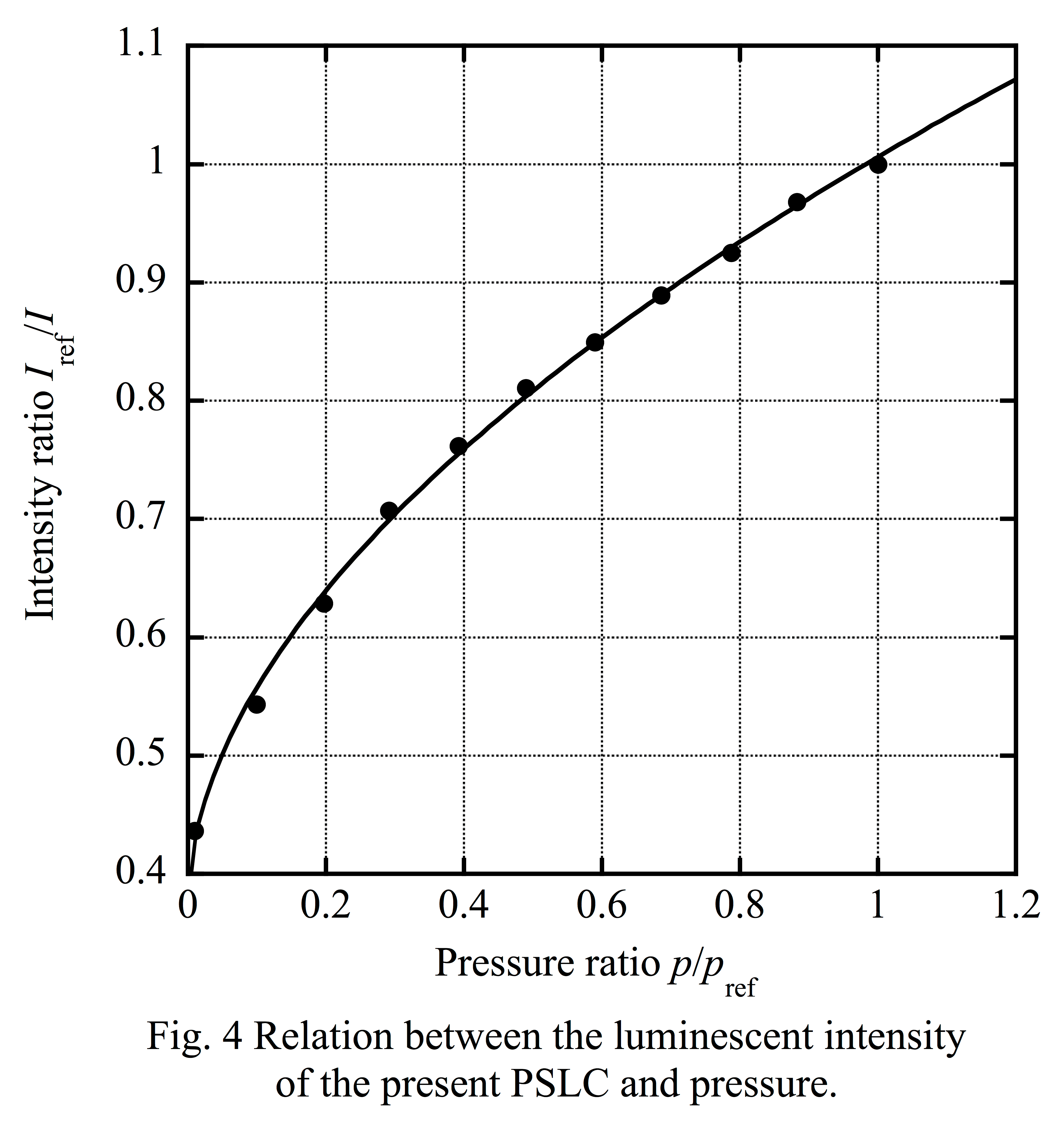

Pressure sensitivity of the PSLC was measured using a calibration chamber schematically shown in Fig. 3. A sample of the ITO glass covered with the PSLC was placed in the calibration chamber filled with dry air. The sample was excited by the light from an Hg-Xe lamp with a blue filter. A 12 bit CCD camera with a 664 ± 40 nm band-pass filter was utilized to measure the intensity of the luminescence emitted from the sample. Area-averaged intensities of the luminescence were used to evaluate the pressure sensitivity. Figure 4 shows the pressure dependency of the developed PSLC in the pressure range from 1 to 101 kPa, where pref=101 kPa. The curves in this figure were obtained by nonlinear least-squares fits of a power function curve to the experimental data. It can be seen that the luminescent intensity of the present PSLC depends on pressure and the pressure sensitivity is comparable to those of conventional PSPs [1].

This work was supported by JSPS KAKENHI Grant Number 26420120.

References

- Liu, T. and Sullivan, J. P. Pressure and Temperature Sensitive Paints. Springer, 2005.

- Huang, C.-Y., Sakaue, H., Gregory, J. W. and Sullivan, J. P., Molecular sensors for MEMS, The 40th Aerospace Sciences Meeting & Exhibit, Reno, AIAA2002-0256, 2002.

- Nagai, H., Naraoka, R., Sawada, K. and Asai, K., Flow diagnostic using PSP and TSP technique in a supersonic micronozzle. Proceedings of the 12th International Symposium on Flow Visualization, Göttingen, 2006.

- Ulman, A., An Introduction to Ultrathin Organic Films from Langmuir-Blodgett to Self-Assembly. Academic Press, 1991.

- Efimov, A., Vainiotalo, P., Tkachenko, N. and Lemmetyinen, H., Efficient synthesis of highly soluble doubly-bridged porphyrin-fullerene dyad, Journal of Porphyrins and Phthalocyanines, Vol. 7, No. 9, pp. 610-616, 2003.

- Isosomppi, M., Tkachenko, N., Efimov, A., Kaunisto, K., Hosomizu, K., Imahori, H. and Lemmetyinen, H., Photoinduced electron transfer in multilayer self-assembled structures of porphyrins and porphyrin-fullerene dyads on ITO, Journal of Materials Chemistry, Vol. 15, Issue 42, pp. 4546-4554, 2005.

- Veselov, A., Thur, C., Efimov, A., Guina, M., Lemmetyinen, H. and Tkachenko, N., Acidity sensor based on porphyrin self-assembled monolayers covalently attached to the surfaces of tapered fibres, Measurement Science and Technology, Vol. 21, No. 11, 115205, 2010.

|