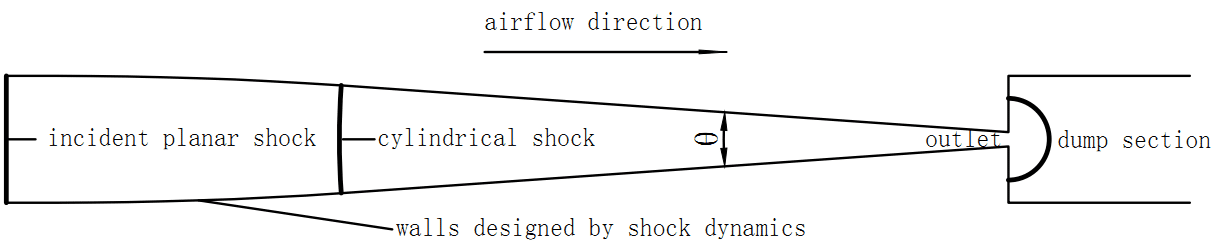

In this paper, we proposed a new type of experimental method for the investigation of ignition behaviors by using a smoothly convergent cylindrical shock wave. The cylindrical shock wave is generated with a specially designed wall contour based shock dynamic theory that can transform a planar shock front into a curved cylindrical one and propagates along a following wedged convergent channel [1] (as shown in Fig. 1), which can be easily performed when install such a test section at the downstream of a rectangular shock tube where premixed combustible gas is introduced in the driven section of the shock tube. The initial planar shock is designed in such a way that its compression is below the ignition point, while the following contraction part is enough for the convergent shock to reach the strength for the combustible gas to burn. Therefore, under such a controllable way a detailed observation might be possible to make clear what happens during the initial stage of ignition and flame propagation. The method is expected to have the advantage of avoiding the complexities of multiple shock interaction, shock wave-boundary layer interactions etc. which may exist in conventional ignition experiments.

Figure1 Sketch of cylindrical shock generation and test section for ignition experiment

The experiments were conducted in a 40 mm X 70 mm rectangular shock tube, of which the driven and test sections were smoothly connected with the same height of 70 mm and filled with 2.70kPa H2+5.90kPa air combustible mixture. High-speed schlieren system with a frame rate up to 20,000 fps and exposure time of 1us was utilized to visualize the flow field. In order to ensure the wall smoothness, no pressure sensors are installed on the wall since any small disturbance may cause remarkable effects on the ignition process. After some pretests, the initial incident shock Mach number was determined to be 2.9, and an angle 8° was fixed for the contraction channel, which enables an enough length for observation and a reliable performance. Two contraction ratios, or two outlet heights, namely 8 mm and 4 mm (contraction ratios of 8/70 and 4/70, respectively) were chosen for the present tests.

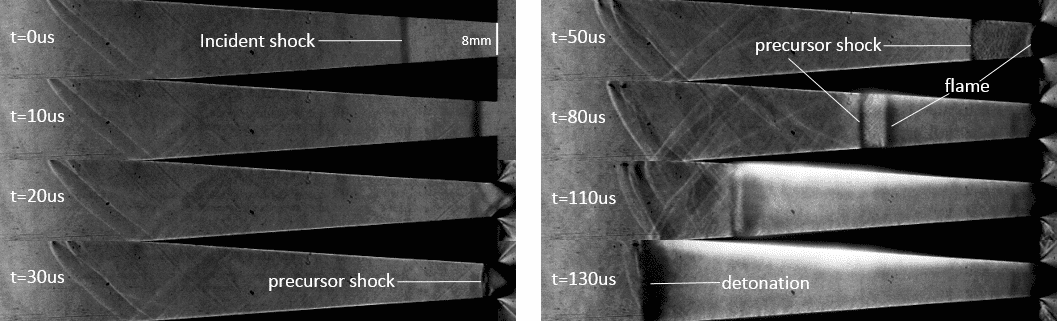

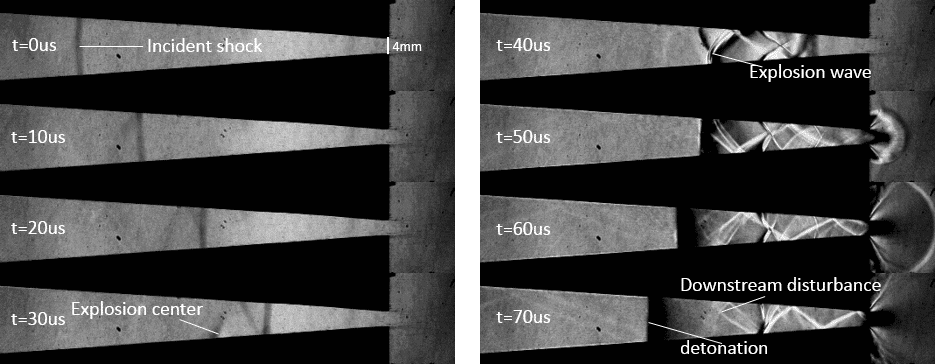

It was found that the ignition process behaves differently for different levels of compressions and two kinds of ignition modes were observed under current experimental conditions. When the intensity of the converging shock is not sufficiently strong (8 mm of outlet height), a mild ignition starts at the vicinity of the outlet as shown in Fig. 2, in which a combustion driven precursor shock and a following flame move towards upstream separately (Fig.2, t=30-110us). However, it can be easily observed that the accelerated flame chases the precursor shock during the process of flame propagation. When the flame overtakes the precursor shock, the overlap results in an onset of a detonation (Fig. 2, t=130us). On the other hand, when the contraction is sufficiently large (see Fig. 3, with height of the outlet to be 4 mm), further enhancement of the converging shock will result in a sudden occurrence of the ignition soon after the passage of the incident shock (Fig.3, t=30us). Such a severe ignition or explosion process generates a strong coupled interaction between the chemical reaction and the explosion wave, which results in a quick onset of a detonation (Fig. 3, t=40-70us).

Figure 2 Schlieren photos for the outlet height of 8 mm

Figure3 Schlieren photos for the outlet height of 4 mm

Reference

- Zhai Zhigang, Liu Cangli, Qin Fenghua, Yang Jiming, Luo Xisheng. Generation of Cylindrical Converging Shock Waves Based on Shock Dynamics Theory [J]. Phy. Fluids, 2010, 22, 041701.