Abstract:

Reflection and transmission of strong shock wave on metal surface induces micron scale material jetting due to imperfection of the surface and instability of it under shock loading[1, 2]. Normally, as the breakout pressure exceeds 20GPa the metal melts and behaves like fluid [3, 4]. Because of the much denser quality of the liquid ejecta, the opaqueness of metal material, and the tiny scale of unit jet, measurements as well as resolved observation of such phenomenon remain a challenge. An alternative solution to this problem is analogous investigations with a more convenient size and material based on proper similarity criterion. It is in this consideration that the present study concerns a millimeter-scale water jetting process which qualitatively simulates the density ratio, Reynolds number and Weber number of realistic micro-jet of molten metal.

In the current experiment, the interaction of shock and interface is confined in a vertical round tube, and the shock load is applied by electrical wire explosion beneath the water surface. High-speed video camera up to a speed of 2000 fps is employed to record the flow field directly. Different explosion energy and tube diameter are examined.

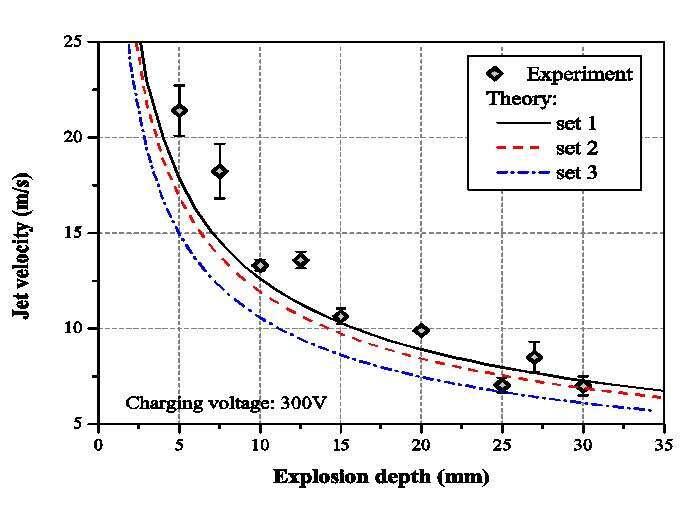

Typical jetting flow pattern is shown in fig.1 (tube diameter 13mm). It is found that the liquid jetting flow is consistent with the structure of molten metal micro jet. The main water column above the explosion bubble reflects the main body of target metal; the smooth leading part of the jet corresponds to the high-speed jetting particles clouds; and the rough root of the jet corresponds to the much denser micro-spall fragments layer. Speed of the jet tip under varied conditions is investigated. Preliminary results indicate that the jet speed increases linearly with the charging voltage. A quasi-one-dimensional theoretical model is then proposed to analyze the results. Qualitative agreement between experiment and theoretical calculation is reached (Fig. 2).

References

[1] J. R. ASAY. Material ejection from shock-loaded free surfaces of aluminum and lead [R]. SAND-76-0542, 1976.

[2] J. R. ASAY, L. P. Mix, F. C. Perry. Ejection of material from shocked surfaces [J]. Applied Physics Letters. 29,184(1976).

[3] Yong-tao Chen, Hai-bo Hu, et al. Experimental study of ejecta from shock melted lead [J]. Journal of applied physics. 111, 053509(2012).

[4] J. L. Shao, L. Tang, P. Wang. Molecular dynamics study on micro-jet from metal surface under shock loading [J]. Procedia Engineering. 2011, 10:3322–3326