ABSTRACT: Zirconium and hafnium diboride based ceramic composites belong to the ultra high temperature ceramic composites (UHTC) category because these materials can be used for applications with temperatures beyond 2500 K. The future re-entry vehicles will be designed with sharp leading edges for reducing the drag forces. During re-entry, the heat flux due to the sharp leading edges becomes so high that conventional materials which have been used so far cannot meet the temperature constraints without melting. UHTCs with addition of silicon carbide (SiC) are candidate materials that can meet these high heat flux requirements [1]. These composite materials are envisioned to act as thermal protection system (TPS) materials in the leading edges, to protect space vehicles from aero-thermodynamic heating during re-entry [2]. During re-entry, aero-thermodynamic heating causes catalytic and non-catalytic surface reactions [3]. Also, oxygen present in the atmosphere reacts and forms new compounds which can change the mechanical and chemical properties of the composites.

Free piston driven shock tube (FPST), operating at an enthalpy range of 5-6 MJ/kg, is used as ground test facility to generate high temperature test gas at the end of the shock tube. Experiments were performed by mounting ZrB2/SiC composite samples in the form of pellets, on the end flange of the shock tube and exposing them to reflected shock waves in presence of oxygen test gas. ZrB2/SiC ceramic composites used in this current study was processed through vacuum hot pressing route at a temperature of 2073 K for 30 minutes. It contains 10 wt.% SiC and MoSi2 respectively. The main objective of the study is to understand the surface reaction process of the ZrB2/SiC ceramic composite when exposed to strong shock heated oxygen test gas. Ultra high pure oxygen at 10 kPa pressure, heated to very high temperatures of about 9000-10000 K (estimated values) for 2-3 ms duration, at reflected shock pressures of about 6.5-8 MPa, interacts with the surface of ZrB2/SiC ceramic. The surface oxidation occurring on the composite materials were studied extensively, before and after exposure to shock heated oxygen. Different characterisation techniques like scanning electron microscope (SEM), energy dispersive spectroscopy (EDS), X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD) etc. were used to examine the surface morphology, electronic structure and crystal structure of as prepared and shock exposed samples.

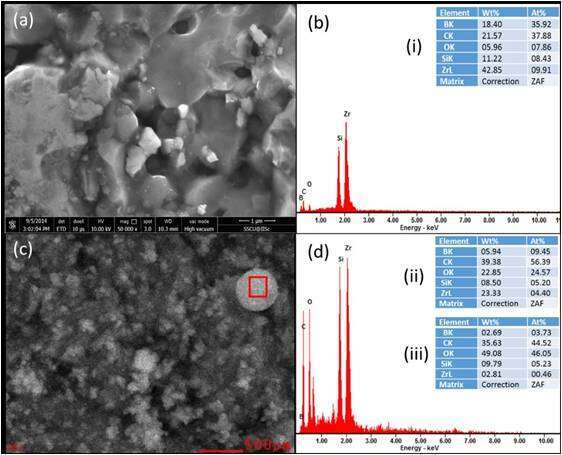

SEM micrograph of the sintered pellets before exposure to shock is shown in Fig. 1a. The corresponding EDS spectra is shown in Fig. 1b and the inset of Fig. 1b shows elemental analysis of as prepared sample, listed in table (i). After exposure to shock heated oxygen, the SEM micrograph shows formation of spherical particles on the surface as shown in Fig. 1c. The corresponding EDS spectra shown in Fig. 1d and the elemental analysis listed in table (ii) in the inset of Fig. 1d, shows an increase in oxygen content in comparison to that of before shock treatment. Also, a further increase in oxygen content is observed from the EDS spectra of a selected area on the spherical surface as shown in Fig. 1c and is listed in table (iii). This quantification is attributed to the formation of silicon dioxide spheres on the surface of the composite after shock treatment. The details of the experimental results obtained will be presented in full length paper.

Fig. 1 (a) SEM micrograph of as prepared ZrB2-SiC sample at 50000x; (b) EDS spectra of as prepared sample; table (i) in the inset shows the elemental analysis of as prepared sample; (c) SEM micrograph of the ZrB2-SiC sample after exposure to oxygen at 50000x; (d) EDS spectra of shock exposed sample; table (ii) and (iii) in the inset of Fig. 1d shows the elemental analysis for full area and selected area on the SiO2 spherical surface as shown in Fig. 1c respectively.

Acknowledgements: Financial support for this research work from DST, DRDO, STC, JATP and LHSR is gratefully acknowledged.

Keywords: ZrB2-SiC composite, TPS materials, FPST, Surface Oxidation

References:

- Davide Alfano, Luigi Scatteia, Frederic Monteverde, Eric Bêche, Marianne Balat-Pichelin: Microstructural characterization of ZrB2-SiC based UHTC tested in theMESOX plasma facility. Eur Ceram Soc. 30, 2345 - 2355 (2010)

- Xinghong Zhang, Ping Hu, Jiecai Han, Songhe Meng: Ablation Behaviour of ZrB2-SiC ultra high temperature ceramics under simulated atmospheric re-entry conditions. J. Comp Sci Tech. 68, 1718 – 1726 (2008)

- Thanganayaki, K. P. J. Reddy, and V. Jayaram: Oxidation resistance studies of silicon carbide thin film in a free piston-driven shock tube. 29th International Symposium on Shock Waves, Madison, USA, July 14-19, (2013)