Pitot probes are often used to determine the total pressure and therefore the flow Mach number of a supersonic flow. These probes are commonly made from stainless steel and hence limited to moderately heated flows, usually up to around 500°C. Otherwise they require an additional cooling system. A potential alternative is to manufacture the probe from Kanthal A1. This super alloy provides a maximum continuous operation temperature of 1400°C and maintains high form stability even for these temperatures.

In this paper, we present a pitot probe design made from sample material provided by Sandvik Materials Technology Deutschland GmbH resulting in a self-made, low-cost, easy-to-use measurement tool. Difficulties during the manufacturing process will also be addressed.

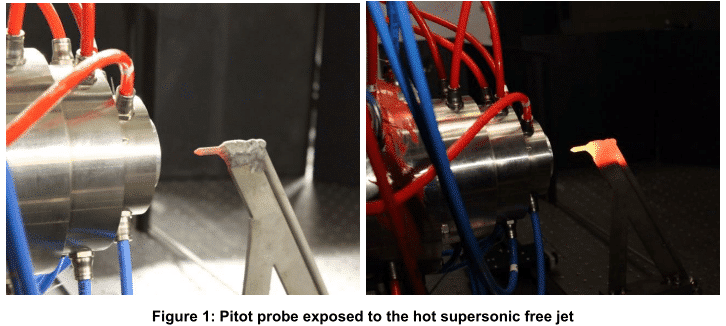

The applicability in hot gas flows is verified in the supersonic combustion test facility at the Institute of Aerospace Thermodynamics (ITLR), which can achieve test conditions with a maximum total temperature of Tt=1300 K and a maximum total pressure of pt=10 bar. Figure 1 shows the probe exposed to a hot, supersonic free jet featuring a Mach number of M=1.5 and a total temperature at nozzle inlet of 1100 K. The left image shows the probe directly after being traversed into the flow, while the right picture illustrates the situation after thermal equilibrium is reached.

The full paper will include measured Mach number distributions for several planes at different axial positions inside the free jet and downstream of the nozzle exit. For each plane, measurements are taken in radial direction starting from the symmetry line. These data will demonstrate that firstly the probe obtains accurate measurements in harsh environments beyond the mechanical limit of standard materials. Secondly, it allows long term operation resisting the high acting forces inside the high velocity, high enthalpy flow field.