A low speed closed loop wind tunnel was designed, constructed and calibrated in Afeka, Tel Aviv Academic College of Engineering. The wind tunnel was built by three students as a graduation project for the degree of B.Sc. mechanical engineering.

The paper introduces the intensive care that was given to all the critical elements of the wind tunnel. The paper describes the test chamber traverse mechanism, the measuring sensor and the 2D acceptance test models. Finally, some representative results of drag and lift polars are presented.

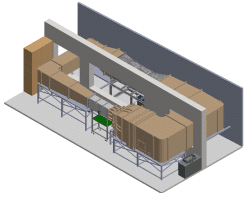

The wind tunnel circuit was made of wood except of the fans section and the test chamber. Over all dimensions are ~5x10 meters. It has a 50 by 50 cm cross-section test chamber and a maximum speed of 60 m/s.

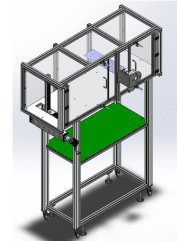

Two channels, lateral and vertical, traversing system with stepping motors is operated by a computer and enables gauge movement for measurements of air velocity mapping in the empty test section as well as in the wake of 2D models for drag measurements.The 1.5 meters long test chamber is made of plexiglass walls and an aluminum construction.

Following the completion of the final assembly of the wind tunnel, flow field measurements across the test section were taken and exhibited a well homogeneous velocity distribution with no more than 1% deviation in the average velocity.

The paper elaborates the detailed design of all the critical elements of the wind tunnel in order to get a quiet flow with turbulence level below 0.2%.