Flexible Long-Range Plasmonic Waveguide for Tb/s Optical Interconnect Application

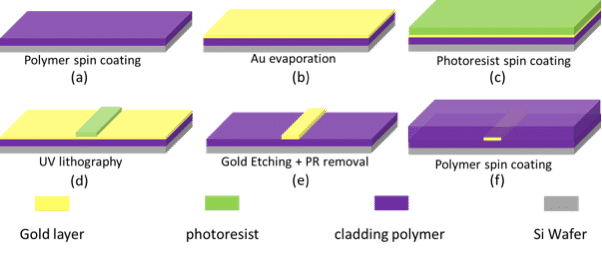

Flexible Long-Range SPP (LRSPP) have been proposed as possible components in datacom interconnect systems1. From the point of view of both processability and reliability the choice of the most convenient polymer to be used as cladding remains an issue. In the context of FP7 IP PHOXTROT, different polymers have been tested. Here we report on the LRSPP potential of Momentive’s research materials. We fabricated LRSPP waveguides (typical Au cross-section 15nm x 10µm, cladding >10µm) after developing a fabrication process based on UV lithography and Au etching (Figure 1). The layers are built up successively onto a Si wafer from which the flexible waveguide can be detached later.

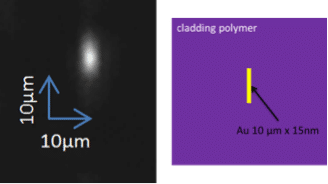

The samples were characterized by injecting TM-polarized light (1.55µm laser) from a single-mode fiber and observing the mode with an IR camera, in the top view and also transversally at the output facet for different waveguide widths (7.5, 10 and 12.5 µm). Figure 2 shows the mode observed at the output, in good agreement with the expected shape obtained from simulation, e.g. a 5x10µm ellipse for the 10µm-wide strip. A 14dB total insertion loss was measured for a 9mm length, corresponding to a ~3mm SPP propagation length. The measured bending losses will also be presented.

|

|

| Figure 1: LR-SPP waveguide fabrication | Figure 2: Output LR-SPP mode imaged at 1.55µm (left) ; corresponding structure (right). |

[1] Jong-Moo Lee, al. Opt. Express, 17(1), 228–234 (2009).

Powered by Eventact EMS