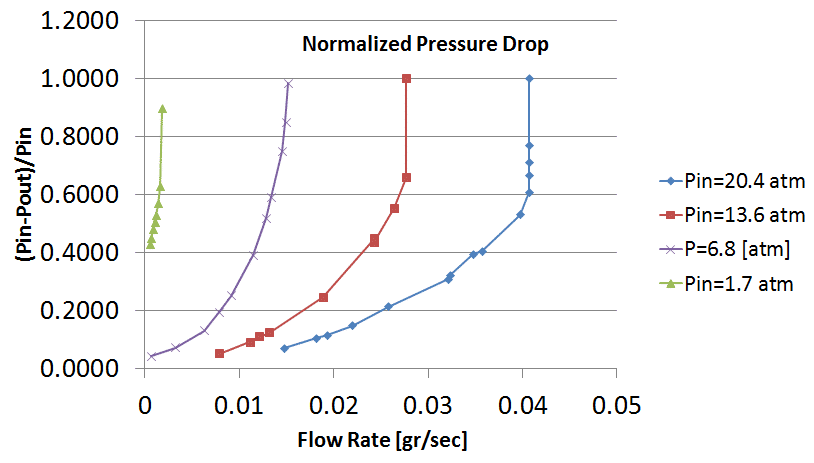

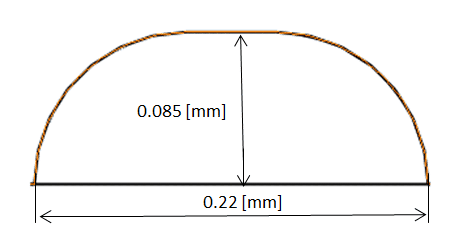

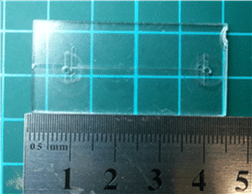

This study presents chocked flow behavior of nitrogen gas in micro fabricated channel at different pressures up to 20 [atm], as presented in Fig 1. Semicircular micro channel was fabricated using wet etching, Fig.2, The channel was made of boronorm glass and sealed using thermal bonding technique that was developed in the laboratory, Fig 3, the chip is compatible with experimental setup that is intended for heat exchanger testing, Fig 4. The setup can introduce pressurized gas up to 200 [atm] at elevated temperatures. We have measured the critical mass flow rate at different inlet pressures at this flow rate the increment of pressure drop over the channel doesnt increase the amount of transferred gas through the channel. Other dependence that was examined is the influence of gas temperature on the critical mass flow over the channel. The results were compared with gas dynamic theory for compressible flows. Micro Channels, compressible flow, Gas Micro Flow, MEMS Fabricated

Fig 1- Pressure Drop as a function of mass flow rate

34 [mm]

Fig 2- Model and cross section of the channel

Fig 3- Examined chip

Investigated HE

Mechanical Pressure gauge Ball valve Pressure regulator Mass flow meter Safety relief valve Temperature and Pressure measure point Needle Valve Fig 4- Test bench